|

Page 1

Go To Page: 1

2

3

4

5

6

7

Back to

Baja Bug Update main page

Disassembly and IRS

Pivot Installation

Type 4 engine and original "swing-axle"

transaxle

This chassis was built in 1968 - that makes it

a "swing-axle" rear suspension and you can see one of the negative

aspects in this photo: the camber of the rear wheels changes

significantly with suspension travel. Here you see lots of

"positive" camber with the suspension on the lower stops; there

would be "negative" camber while on the upper stops.....

Additionally, the total suspension travel is limited by the

"swing-axle" design so the "IRS" rear suspension is much preferred

in off-road use. Our suspension update will convert this car

to a rear suspension system identical to that on our 5/1600 car,

giving us as much as 16" of rear wheel suspension travel while

minimizing camber changes.

Step 1 - remove the engine and swing-axle

transaxle

With the engine and transaxle out of

the way, we can begin the conversion to IRS rear suspension.

While it's out of the car, Trevor plans to freshen up the engine and

install a new camshaft that will better match the intended purpose

of the car (a pre-runner).

The swing-axle suspension beam and "frame

horns"

The frame horns must be modified to allow

installation of the inner IRS pivot brackets - they locate at the

intersection of the beam and frame horns and as you can see here,

there's a bunch of structure/stuff in the way..... Some of the

hardware in this photo is a "hard mount" kit for mounting of the old

transaxle - that'll all go in the scrap bin and we'll fabricate new

mounts to interface with the "mid-mounts" that'll be part of our

new "Bus" transaxle.

Beginning the process of fitting the IRS pivot

Here we're using a commercially supplied "jig"

to position the driver's side IRS pivot so that we can determine

where to clearance the frame horns. The pivot will be inset

into the horn so that the innermost rear edge of the pivot is

essentially flush with the frame horn, requiring that we cut a

fairly large hole in the horn for a portion of the pivot to reside

inside the horn. Ultimately, we want to fit the pivot bracket

so that the jig bolts flat to the torsion housing spring plate cap

location while the boss at the pivot end is centered in the pivot

bracket. We'll try to remove as little material as

possible but may end up needing to close some gaps - it's a trial and

error process when you do it as infrequently as we do......

Frame horn cut for the IRS pivot installation

Here you can see the frame horn opening with

the pivot close to its final position. These are heavy duty

"race" IRS pivots, same as on our 5/1600 car. We had the

brackets but had to fabricate special "shoulder" nuts to weld on to

the pivot faces that are inside the frame horns and we had to turn

down the bolt heads to act as the outer bearing surfaces - the bolt

head needs to fit snugly inside the hole in the outer plate of the

IRS bracket.

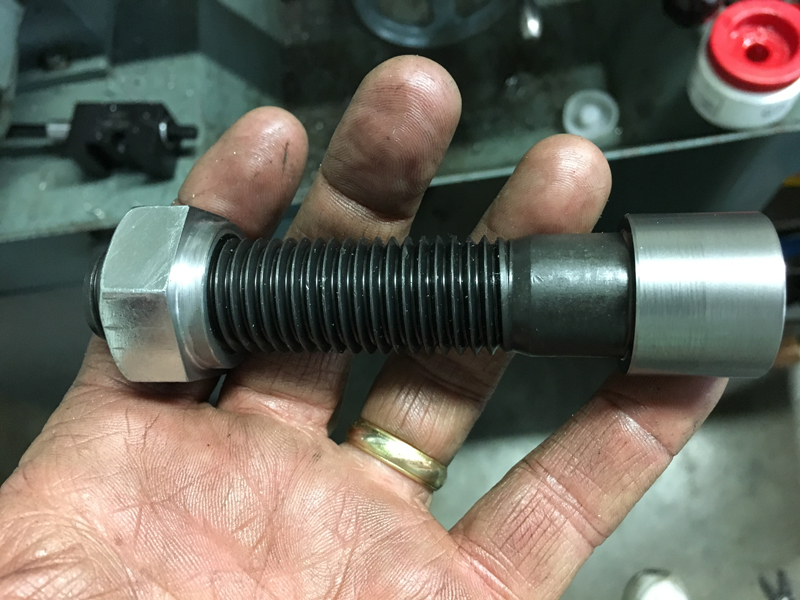

Custom Pivot Bolt and Nut

We modified the bolts and nuts from

commercially available stock - both the bolt heads and the nuts are

machined to act as bearing surfaces with the pivot brackets.

The pivots are heavy duty "race" parts and these pivot bolt

assemblies are much larger than stock. The nuts weld to the

pivot brackets on the face that is recessed inside the "frame

horns".

Pivot

bracket inset into frame horn

You can see that we ended up cutting the hole a

bit over-size so we had to make a "filler" plate to close the gaps.

The frame horn area just to the right of the rear edge of the

bracket is rough because that's where the stock parking brake cable

exits. We had to remove the cable support structure, leaving

the area a bit disturbed - we'll close up and smooth over the area

before moving on. Also, the frame horn "seam" has a flange

that intrudes into where the trailing arm will mount - we'll trim

that back as necessary and re-weld the seam. Surprisingly, a

fair amount of trimming of the actual pivot bracket was necessary to

achieve the correct positioning (we had to remove lots of material

to get them to sit tight to the beam where the jig wanted them).

Final IRS pivot location, ready to be tacked in

place

Now that all the IRS bracket trimming is

complete, you can see that the jig bolts flat to the spring plate

cap mount (left side of the jig) and the jig boss is centered in the

bracket. Trevor tack welded the bracket in place, removed the

jig then fully welded the bracket. The passenger side IRS

pivot was installed in the same way. Next, we'll

grind the welds around the bracket to produce a smooth transition

then paint.

We're using spare 5/1600 parts for this

conversion - trailing arms, spring plates, torsion bars and axles -

all parts that have been raced multiple times, then retired to serve

as spares. One of the trailing arms was a bit "tweaked"; it

was damaged in our 2012 Baja 500 roll-over. We were able to

return it to serviceable condition without too much trouble and it

should do well in this pre-runner. Everything else seems to be

in good shape so we'll just clean it up, paint it and bolt it on -

the car will be back on the wheels in no time!

Passenger side IRS pivot final welded and ready

for the trailing arm.

We still need to install a small pivot bolt "locking" device to keep

the pivot bolt from rotating during service - the trailing arm would

otherwise be able to rotate the bolt as the suspension cycles

up/down and it could eventually "unscrew" all the way out and we'd

lose the wheel on that side.....

Driver's side Pivot pin "lock"

This lock secures the pivot pin so that it can't

rotate as the trailing arm articulates - it's just a bolt head

welded to a tab that engages the Allen head of the pivot bolt,

restraining it from rotating while the tab is secured with the small

bolt you see at the top.

Page 1

Go To Page: 1

2

3

4

5

6

7

Back to

Baja Bug Update main page

|