|

Engine case halves, heads and connecting rods

ready for reassembly

All the machine work required to bring these components "within

spec." has been completed and

they are ready for reassembly once the remaining components are on

hand. Yes, that's one of our old "roll-over" bodies

in the background (we don't throw much away);

Trevor is going to turn it into an artistic shop couch......

Our new CP Carrillo Pistons

New, to fit our increased bore size and with a different profile

to increase the compression ratio. The wrist pins are a

slightly different size than the originals so we'll need to re-bush

the connecting rods to suit.

Crankshaft with rods installed, ready to close

Finally, all the pieces are coming together again! The

wrist pin bushings in the rods have been sized, new main and rod

bearings installed, sealant applied, assembly lube liberally spread

around the rotating assembly and ready to "close"!

Case halves reassembled with 3 of the 6 pistons

installed

We cheated a bit: we installed the pistons and rods into this

side of the case then secured them to the crankshaft before

installing the other case half. The pistons on the other side

will have to be installed from the "top" of the cylinders and the

wrist pins installed through small access holes provided in the

case... We'll need to fabricate a couple of special tools to

accomplish that part.

Custom tool for installation of the center

cylinder wrist pin

Here, you can see the wrist pin installed on the special tool we

fabricated for the remaining "center cylinder". The piston is

installed after the case halves are assembled, requiring that the

connecting rod and piston be assembled "blind" - through a small

access hole. It's bit of a "fiddly" job but with this

simple tool it only took a few minutes. Installation of the

wrist pin retaining clips was accomplished with a modified pair of

long nose pliers. The two "outside cylinders" require the same

process but they're much easier as they don't require the "long

reach" tools.

"Short Block" on the engine stand after

installation of the remaining pistons

Ready to continue assembly to a "long Block" configuration.

Before installing the heads, we carefully measured to confirm

piston/head clearance at Top Dead Center - even though the piston

production documents indicated that they should be fine....

The next hurdle is making sure that once the valve train is

installed and timed we don't have valve interference issues.

Again, the piston production documents indicate that it should be

fine but we're not making any assumptions....

ARP head studs installed

These high strength studs replace the stock Subaru head bolts -

shouldn't have any problems with the heads coming loose...

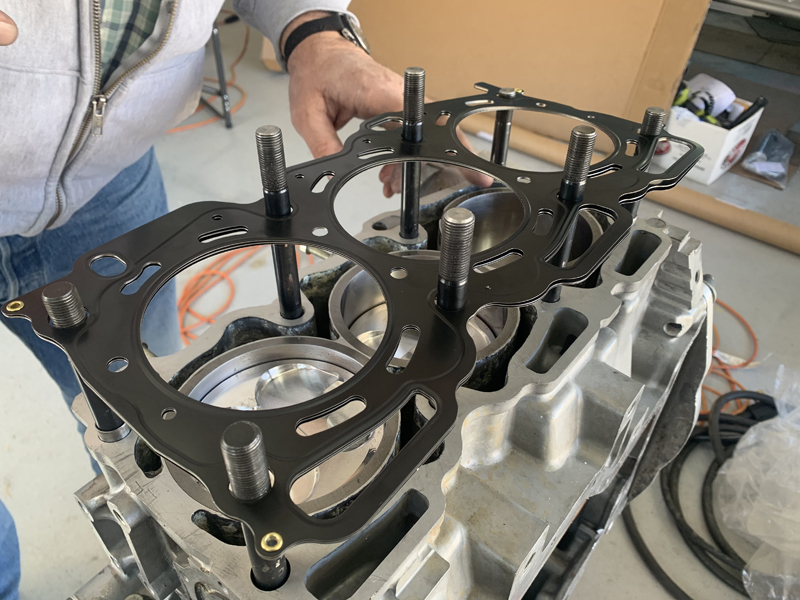

Installing one of the Cometic MLS head gaskets

These multi-layer head gaskets are the preferred choice for high

performance applications

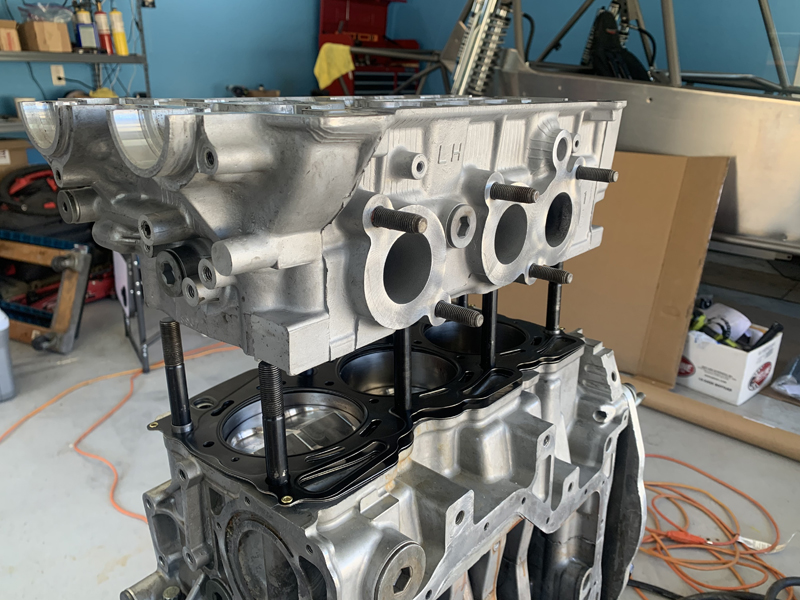

Installing the "1, 3, 5" cylinder head

With the studs and gasket installed, we can slide the head into

place. We were careful to insure that the studs were installed

into the case correctly so that they didn't protrude into the space

the cams will occupy later.

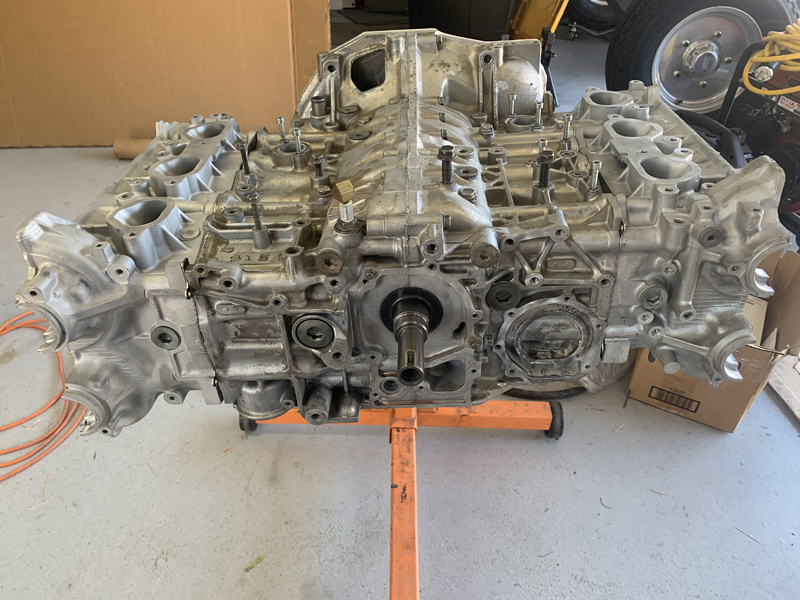

Both heads installed, awaiting final torque

We didn't have enough hardened washers for all the studs so we

stopped at this point. The stud washers are not a size

generally available locally so I had to modify what I could

get locally... Once we install the washers and torque the

studs to specifications, we can start

assembling the valve train, oil pump, water pump, belt drives, etc..

|