|

The Subaru EG-33 engine

is normally a "wet-sump" type engine - that system works fine

for vehicles run on pavement but has proven to be less reliable

in off-road conditions, leading to bearing failures. In

our pre-runner application, a "dry sump" oiling system is much

preferred. There are commercial "bolt-on" dry sump systems

available but we already have the "expensive parts" on hand

(they came ready for installation with the engine when we

purchased it) so we're fabricating the remaining parts we need

ourselves. Essentially, we do away with the stock oil pump

and oil pan in favor of a "dry sump" pump assembly that consists

of both a scavenge (oil return) pump and an oil supply

(pressure) pump. The scavenge pump continuously returns

the oil draining from the bearings to an external oil tank.

The oil tank feeds the input of the oil supply pump, insuring a

steady supply of oil to the engine.

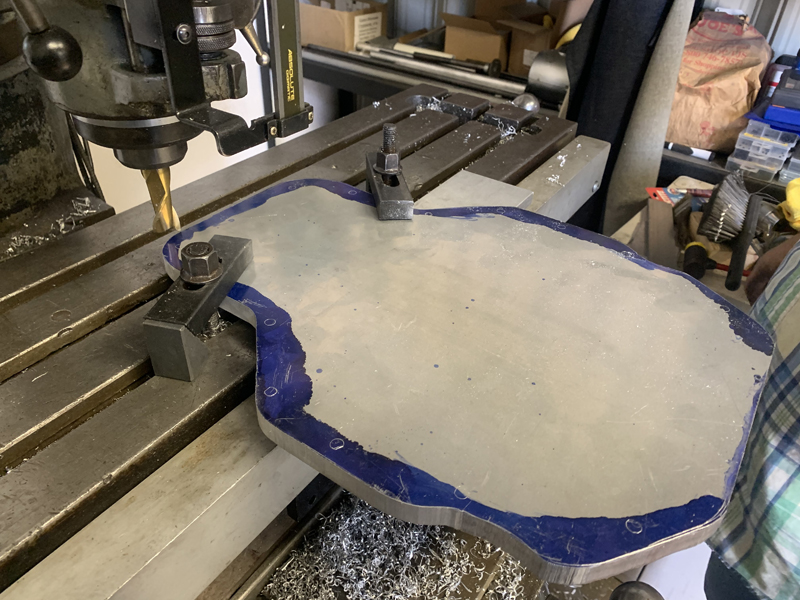

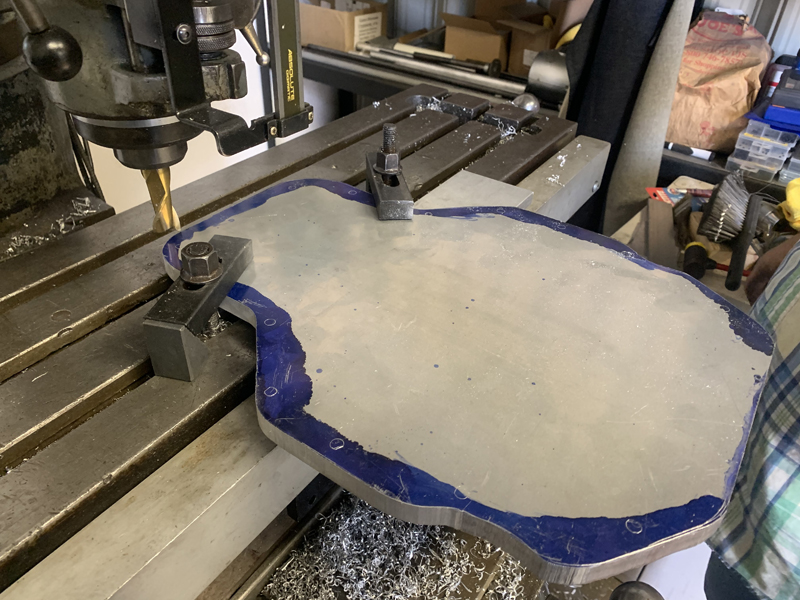

Dry Sump crankcase plate being milled to

shape

We eliminate the need for a stock oil pan; the oil supply

will be contained in an external tank. We still need to

close the gaping hole that would otherwise exist when we remove

the oil pan so this plate is needed to replace it. Here,

you see the sump plate being milled to shape. Next, we'll

drill the mounting holes and mill the "inside face" to direct

the draining oil to the scavenge pump pick up fittings.

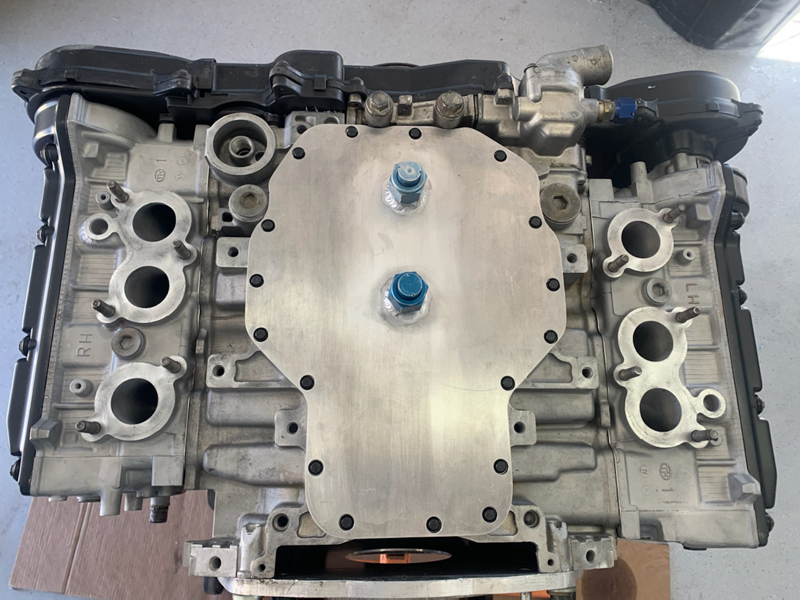

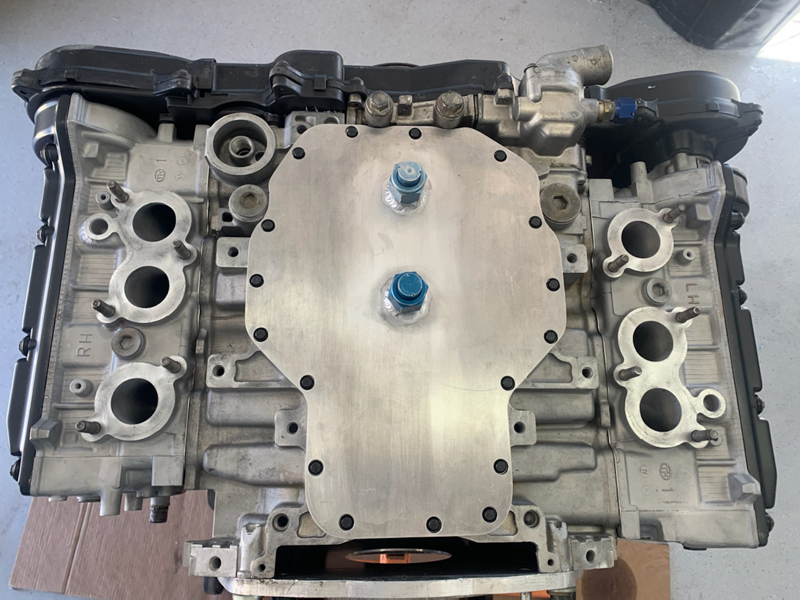

Sump Plate mounting holes drilled and

counter-bored

This is the "outside" face of the sump plate; the two large

holes near the center of the plate are where the scavenge pump

hose fittings (one is visible in the upper left corner of this

photo) will be welded in place.

Sump Plate "inside" face milled to shape

We milled the inside face of the sump plate to help direct

the draining oil towards the scavenge pump pick up fittings.

The scavenge pump will ensure that very little oil collects

inside the engine - it will immediately be pumped to the

external oil tank for use by the oil supply pump. We

provided two pick up fitting locations but we have only one

scavenge pump circuit. We'll use only one of the pick up

fittings; once we determine which location works best, we'll

make the pickup connection there and the other fitting will be

capped.

Scavenge Ports welded in place

Trevor welded these at home - it was a bit of a challenge

with his garage 220V circuit breaker limiting the current he

could apply...

Sump Plate temporarily installed to check

the fit

It looks like a good fit - now we just have to etch and

apply the Alodine "conversion" process then "final" install it.

Dry Sump Pump

This is the "dry sump" pump that replaces the stock oil

pump. It's an external pump "assembly" with two

independent pumping sections on one shaft - one for "scavenging"

oil from the crankcase and returning it to the external oil tank

and the other for delivering oil from the storage tank to the

engine under pressure. The pump will be belt driven by the

crankshaft via the extended shaft seen protruding from the

plastic cover.

2-Stage oil pump disassembled for overhaul

The pump was missing seals and not correctly assembled when

we received it with the engine core. Trevor disassembled

the pump, inspected it and replaced all the seals.

Fortunately, aside from the missing seals, it was in excellent

condition. Once reassembled and installed, Trevor operated

the pump with a drill motor to verify function and check for

leaks. The pump was clearly working; the pressure lines

"flexed" and the oil quantity in the tank dropped as all the new

lines filled with oil.

To perform an initial oil pressure adjustment, we again used a

drill motor to simulate idle operation. We noticed that

the oil quantity in the tank didn't stay constant - oil was

accumulating in the engine sump faster than it was being

scavenged (the pressure pump is twice the size of the scavenge

pump). We installed an oil pressure test gage to see why

that might be; we found the oil pressure was quite high, leading

to the in/out flow imbalance. Fortunately, pressure is

easily adjusted via a bypass valve in the oil pump. With

the idle oil pressure adjusted to a "normal" range, the scavenge

pump now keeps the engine sump "dry" as it should when we turn

it with a drill motor.

With the engine running, we found that the

scavenge oil pump works fine up to about 4000 RPM but beyond

that point doesn't keep up with the amount of oil flowing into

the pan from the bearings. We believe that this is due to

a "vortex" being formed directly above the oil pickup at high

flow rates (high RPM's). The vortex allows air to be

entrained, reducing the scavenge pump's ability to keep up with

the amount of oil flowing into the pan... After

researching the issue, we believe the solution is to incorporate

"vortex breakers" into our oil pan.

They're essentially cover plates that only allow the oil to be drawn from around their perimeter

rather than from directly above the oil pickup fittings.

Milling the "Vortex Breaker" interior profile

Milled to shape

These are simple parts; their only function is to keep the oil

flowing to the scavenge pump with a minimum amount of air

entrained. Obviously, if the scavenge pump keeps the oil

level below the top of the slots, air will be entrained - but

that's not a problem as long as there isn't a net transfer of

oil to the crankcase from the tank...

Vortex Breakers in position, ready for welding

Trevor will weld the Vortex Breakers in place over the scavenge

pump oil pickup locations. This design is essentially what

was recommended by the manufacturer of our dry sump pump; we

simply took the idea and scaled it to fit our pan. The

slots total nearly two square inches on each while the area of

the actual pickup is closer to .44 inches square. The

covers sit well above the actual outlet (there's a "well" under

each, not visible in this photo) and shouldn't cause any flow

restriction.

Vortex breaker welded to pan

We have a single stage scavenge pump so we can use only one

oil pickup location at a time. As the car's body angle changes (up

or down hill), the oil level will vary a small amount as a

result. We're consciously choosing not to manifold more

than one pickup port to the scavenge pump to avoid the scenario

where one port is "uncovered" while the other is submerged.

In that situation, rather than evacuating oil, the pump will

draw air from the uncovered port until the oil level rises to

cover both ports... The other pickup location visible in

this photo tends to be the "high point" in the pan on level

terrain and wouldn't help as a result.

In addition to the "Vortex Breakers", we

fabricated and installed a custom "Windage Tray" and modified

the stock oil pump to act as an additional "scavenge" pump.

We also re-configured the "dry sump pump" so that the scavenge

pump portion was the larger of the two pump sections. We now have good control of the oil flow through the engine and

back to the oil tank; the oil level in the tank and

crankcase stay within normal limits at all rpm's. |