|

An exhaust system that meets our needs is

not readily available commercially; we'll have to design and

fabricate our own. There are numerous considerations

including: fit, performance, sound, etc.. Trevor has done

extensive research and has identified the basic parameters; now

it's a matter of routing and mounting to be decided upon.

He has decided upon a "6 into 1" collector arrangement with a

single muffler to be located in the space behind the engine.

There are other systems that will need to be located nearby - we

need to be careful to consider their requirements... Once

the routing is determined, we'll start piecing together all the

bends and straight sections of tubing until we have the shapes

we want. This may be a bit of a trial and error process;

nothing will be final welded until everything fits as planned.

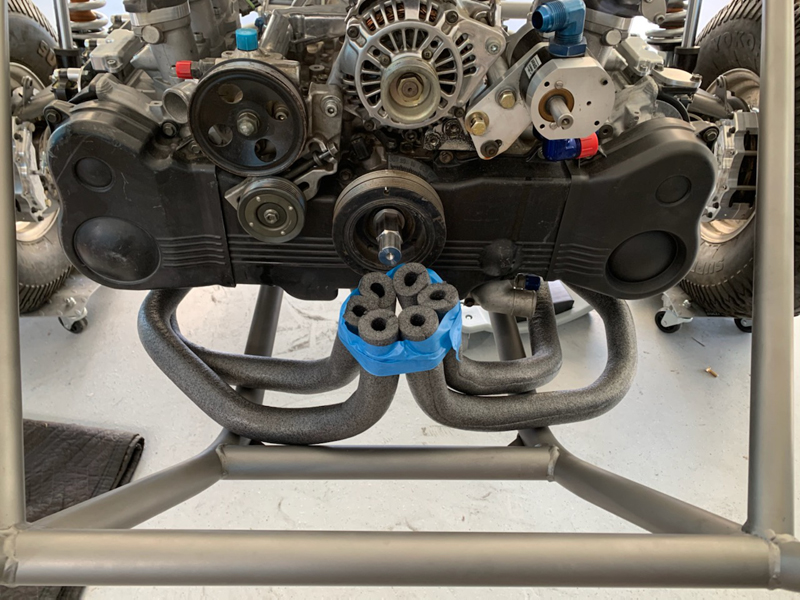

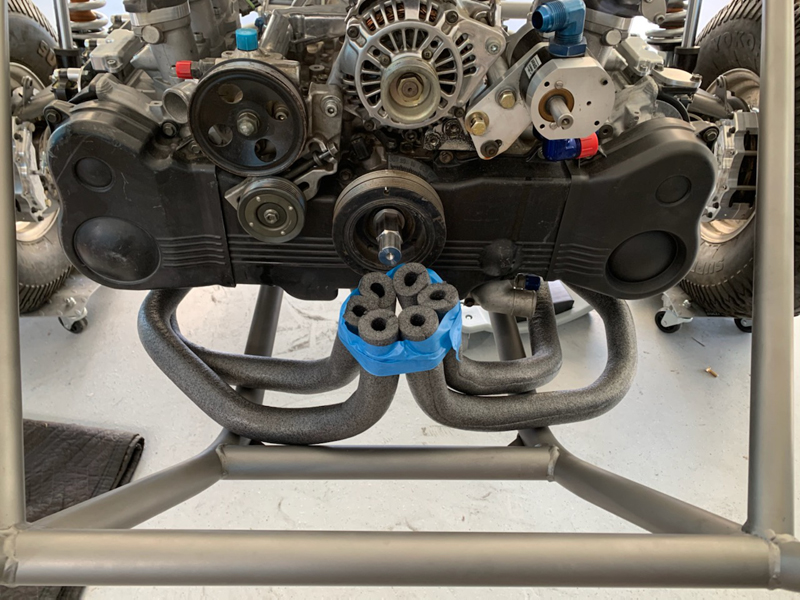

Raw components we'll use to create the exhaust system

These are just some of the stainless steel tubes we'll use

to create the individual exhaust tubes. They'll be welded

to exhaust flanges in groups of three; one "group" flange

per side. They will be routed low (but above the skid

plate) and then terminate behind the crankshaft pulley where

they will meet the "6 into 1" collector. The collector

will have a "V" clamp on the muffler side; that will allow us to

change muffler arrangements without any cutting/welding.

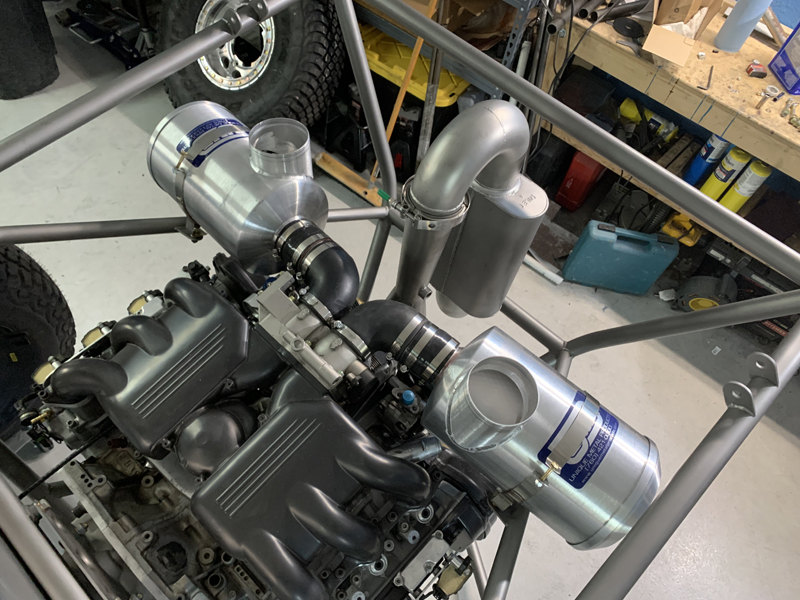

"6 into 1" collector

Rather than use two "3 into 1" collectors, we

are using a single "6 into 1" collector. The "slip joints"

will allow us to keep the left and right side manifolds separate

for installation, then combine them with this collector before

the muffler.

Exhaust system "mock-up"

This is a rough approximation of the desired configuration;

we'll de-conflict any problem areas during the actual

construction. We want all the exhaust tube to be equal

length and to be arranged in the collector in the most efficient

orientation - that's a challenging process but we'll get it

done!

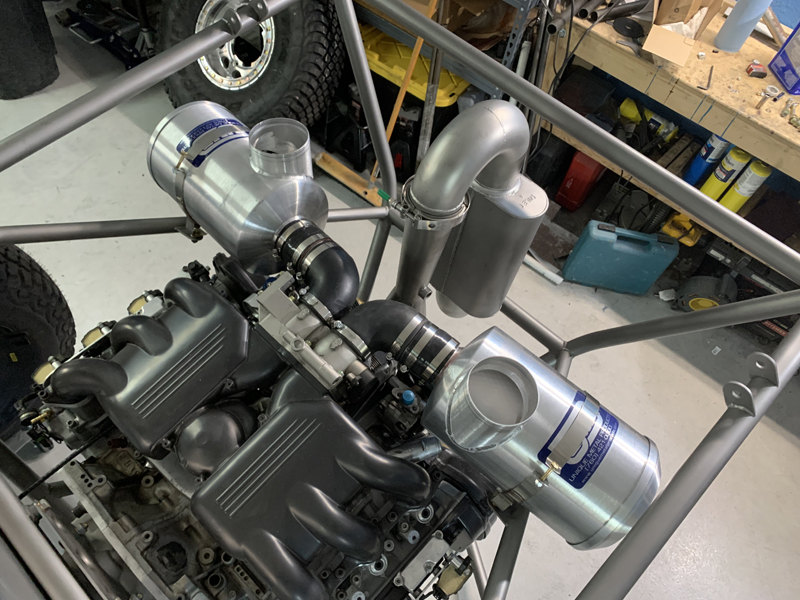

Exhaust System Fabrication

Routing all the tubes while keeping them the same length and

remaining within the confines of the cage is a challenge...

Bottom View

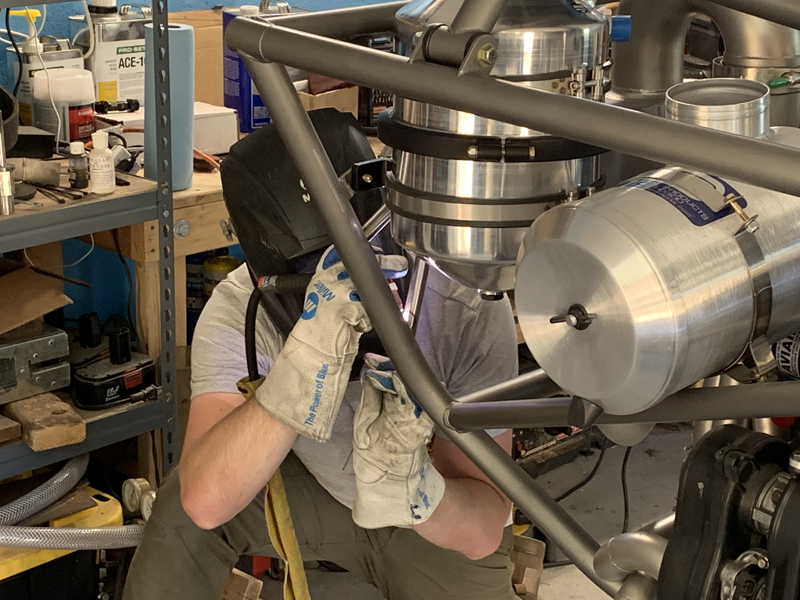

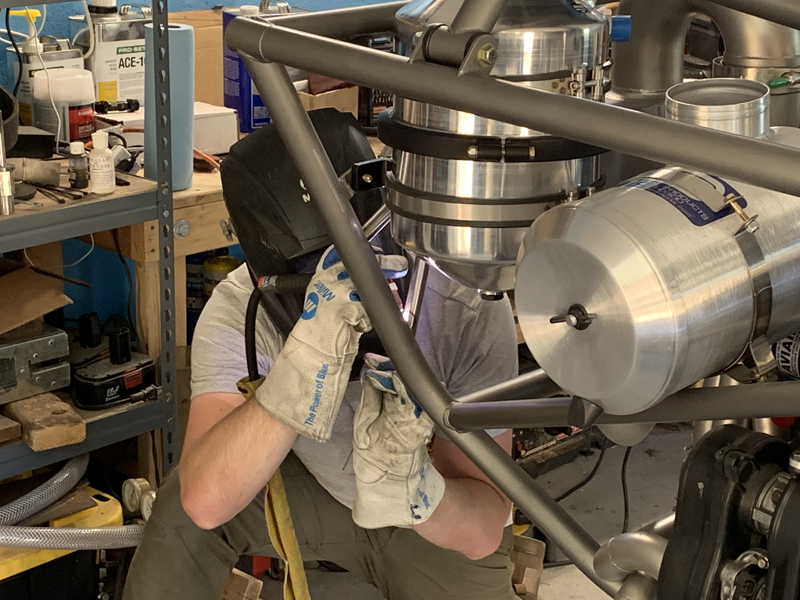

Welding one of the tubes

Each of the six individual tubes were custom fit to

the engine and the other tubes; this tube is being

final welded with an internal Argon purge gas supply.

Once all six are final welded, they'll be reinstalled and welded

to the engine exhaust flanges.

"V-band" joint between the collector of the muffler

We chose to include a V-band connection between the

collector and the muffler to allow us to try different muffler

configurations without the need to cut and weld.

Initial Muffler configuration

This is the muffler configuration we are starting with;

we'll be able to easily change configurations later if we

choose. The outlet of the muffler will have an

elbow and "Supertrap" spark arrestor also.

Almost there

Just a little final welding to accomplish then off to bead blast

for uniform finish. The muffler is stainless steel so the entire

system will develop that stainless steel "patina" we like.

Engine air filter configuration

We experimented with several different air filter mounting

configurations; this one presented the best compromise in our

opinion. We wanted the air filters as close to the

throttle body as possible to minimize ducting losses, they

needed to be mounted securely, be easily serviced and had to

leave enough space

for the remaining equipment installations (oil reservoir, power

steering reservoir, etc.).

Trevor welding the oil tank support

structure

Our "Dry Sump" engine oiling system

requires an external tank to hold the oil; it needs to be

located near and above the system pump . This is a

convenient location that affords easy access for filling and

draining - it's also as close to the dry sump pumps as we can

get it...

Mount fabrication complete

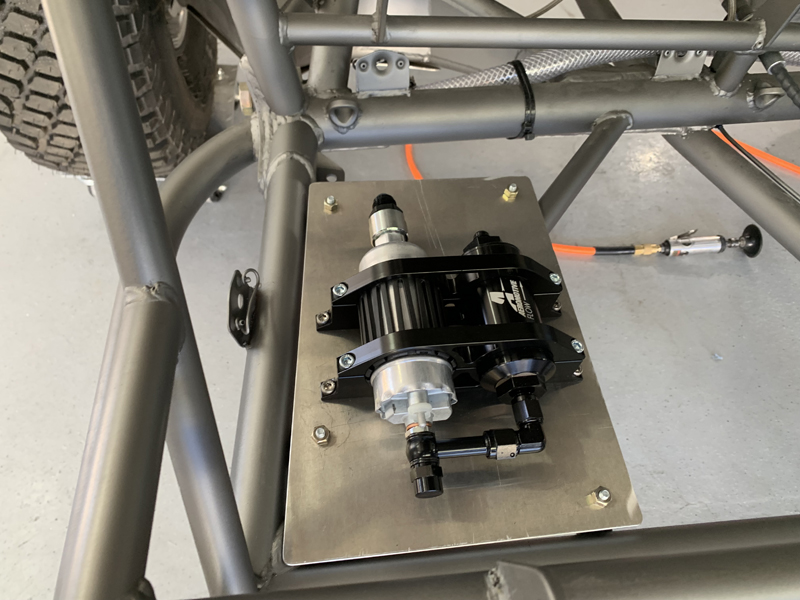

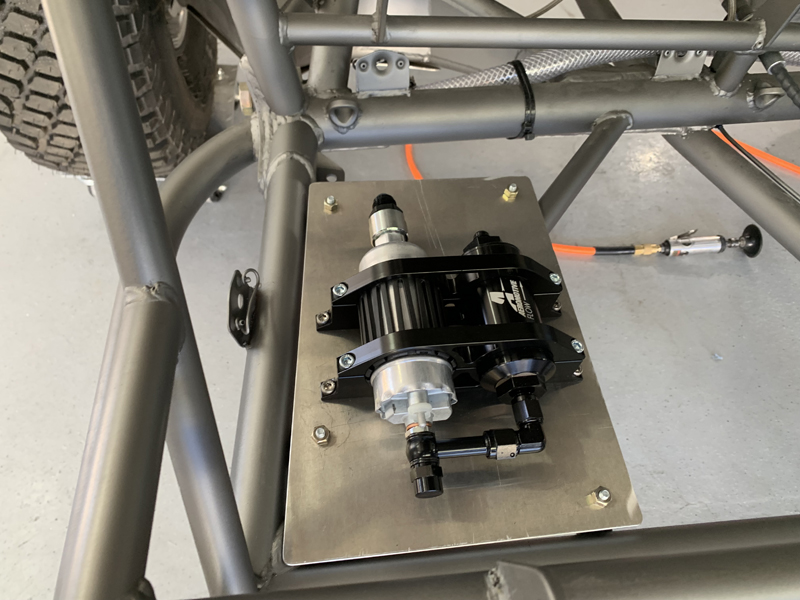

Fuel pump/filter assembly mounted

We mounted the fuel pump/final filter

assembly on an aluminum plate that's secured under the rear

seat. The plate is mounted to the chassis with rubber

"vibration isolation" mounts to minimize any pump noise in

addition to reducing wear and tear on the pump due to vibration.

Since this isn't intended to be a "race car",

we've chosen not to install a "back-up" fuel pump. We'll

carry a spare since failure of the fuel pump would otherwise

require recovery by tow or trailer... The assembly is

easily accessed and serviced by removing the body side panel - a

few minute job with a screwdriver...

|