|

We have five main areas of "plumbing" to

contend with: power steering, brakes and clutch, fuel, oil and engine cooling.

The power steering plumbing has been

partially complete for months. The control valve to steering

rack lines are complete and installed; the lines between the

control valve and pump were installed on the control valve and

left long for us to complete once the engine installation was

complete. We're now at that point.

We completed the brake and clutch plumbing

several months ago when we installed the pedal assembly.

We recently filled both those systems with brake fluid and bled

them until the pedals were firm and they seemed to operate

correctly. We've subsequently decided to change the clutch

master cylinder to a slightly smaller bore in order to "lighten"

the clutch a bit. The brakes seem fine at the moment but

we have a brake pressure gage on order to confirm that the front

and rear brake pressures are in the "ballpark" with moderate

pedal pressure. We can change those master cylinder sizes

if needed also.

Our fuel system is fairly simple; we come

out of the fuel cell to a "pre-filter", into the fuel pump, out

of the fuel pump to a fine "post-filter" then to the fuel rails.

To regulate fuel pressure, we come out of the fuel rails to an "Aeromotive"

fuel pressure regulator that returns excess fuel to the fuel

cell.

Our "dry sump" oil system is more

complicated than the "wet sump" system found in most autos.

Our engine doesn't retain any oil in the "sump"; oil is stored

in an external oil tank that collects oil "scavenged" from the

engine. That tank supplies oil to an external oil pump

that is actually two pumps in one; a "scavenge" pump that

recovers oil from the engine after it has done it's job and a

"pressure" pump that delivers oil to the oil filter then back to

the engine under pressure. This "dry sump" system will

ensure a constant supply of oil to the engine under all

conditions.

Engine cooling is accomplished by a large

radiator with electric fans located just above our fuel cell.

The radiator is supplied with "ram air" via a duct between the

roof and roof rack when the car is in motion and the fans when

the car is stationary. To compliment the radiator, we have

a "surge tank" in addition to an "overflow tank". The

surge tank serves to help eliminate trapped air in the cooling

system while keeping the coolant level full. The overflow

tank provides a place for excess coolant to be retained when

necessary. It's a fairly simple cooling system but will

require a little bit of fabrication to make everything work well

together. The plumbing will consist of 1 1/2" aluminum and

silicone tubing with a few smaller fittings required for

connecting the surge tank.

Some of the fittings and hoses we'll use to

plumb the fuel and oil systems

Rather than order custom made hose

assemblies for all the different connections we need, we chose

to order the necessary fittings and bulk hose so that we can

fabricate our own custom hoses.

Oil pump to oil filter adapter hose

assembly

We installed a "fire sleeve" on this particular hose for

abrasion resistance more than fire resistance.

Fuel pressure regulator

Filtered fuel is supplied directly to the fuel rails from

the fuel pump; this device, also connected to the fuel rails,

bleeds off excess fuel and returns it to the fuel cell,

regulating fuel pressure as a result. This assures a

constant, stable supply of clean fuel at the correct pressure

while reducing or eliminating the threat of "vapor lock".

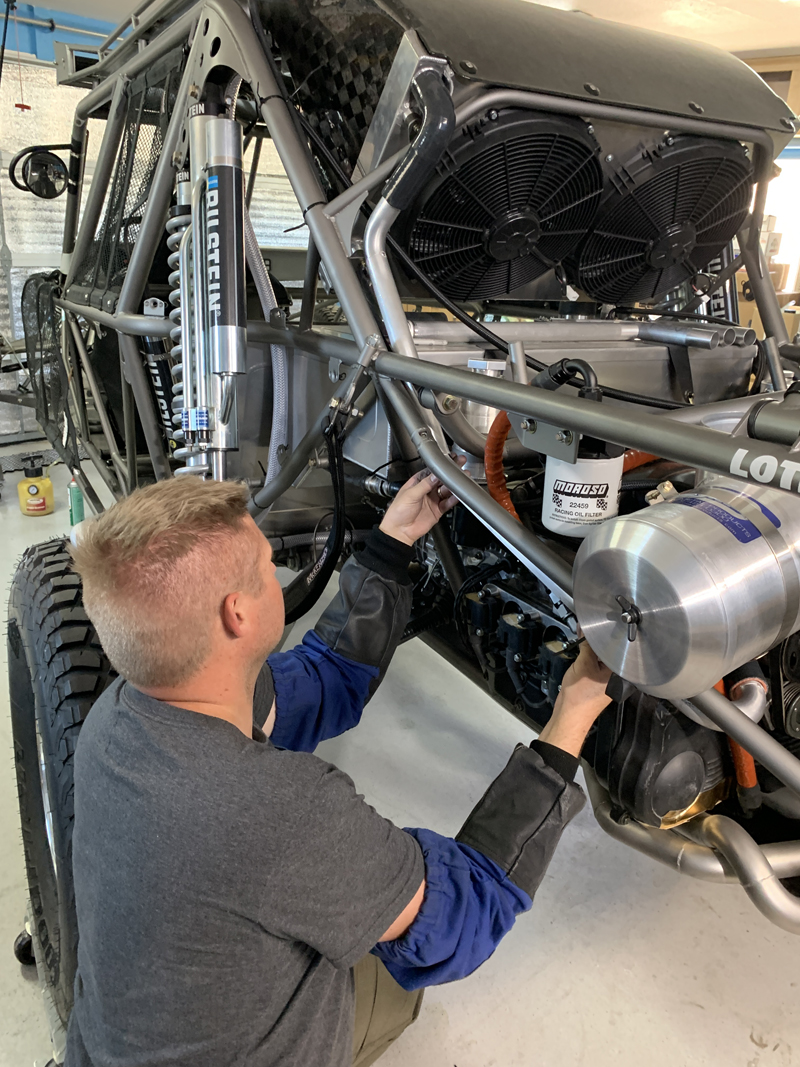

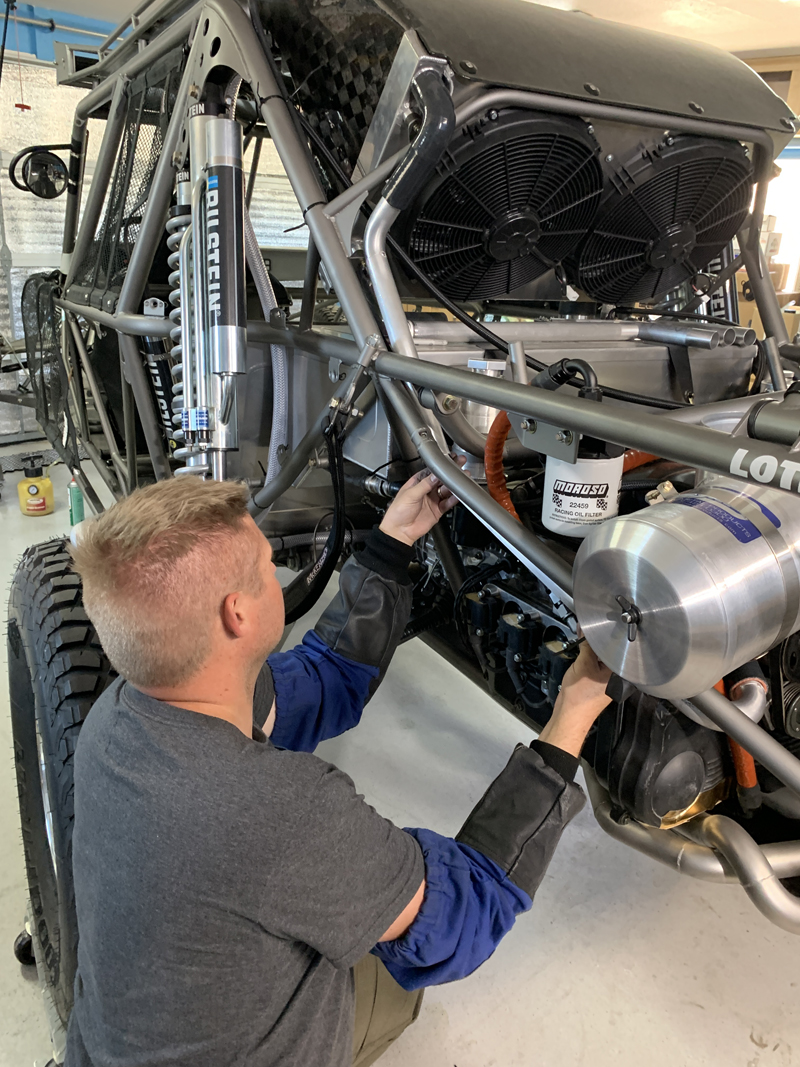

Dry sump system plumbing complete

All the hose assemblies for the oiling system are now

complete and temporarily attached. We still need to flush

and inspect each one, then final install them. Given the

proximity to the engine and exhaust system, we elected to "fire

sleeve" all the oil hose assemblies.

Trevor fabricating cooling system hard

tubes

Trevor started with 8' of straight aluminum tubing and a few

pieces of bent aluminum and silicone tubing. He then

pieced it all together to fabricate the two main coolant tubes

between the engine and radiator

Coolant tubes

and thermostat housing leak/pressure tested

Trevor had to modify the thermostat housing in order to

clear the exhaust headers. Once everything was welded, he leak

checked each tube and made small weld repairs as necessary.

He then etched (you can see the powdery residue on the tubes)

and "Alodine" treated all the aluminum tubes for corrosion

protection.

Engine coolant inlet line fitted

This is the line from the radiator that feeds the engine's

coolant pump. It'll be supported/secured in several

locations to ensure there are no chaffing, bending or vibration

issues.

Inlet line connected to the thermostat

housing

The thermostat housing needed to be modified a bit to clear

the exhaust manifold with plenty of room. Trevor cut the

stock housing then added sections of bent aluminum tube to

create the shape we needed.

Radiator return line fitted

This tube returns hot coolant from the engine to the

radiator.

Radiator return line engine connection

We chose to run the hard tubes along the bumper tubes as

much as possible. That gives us an easy solution for

securing the tubes, keeps them somewhat protected and keeps them

situated as "compactly" as possible. "T bolt" clamps to

come next.

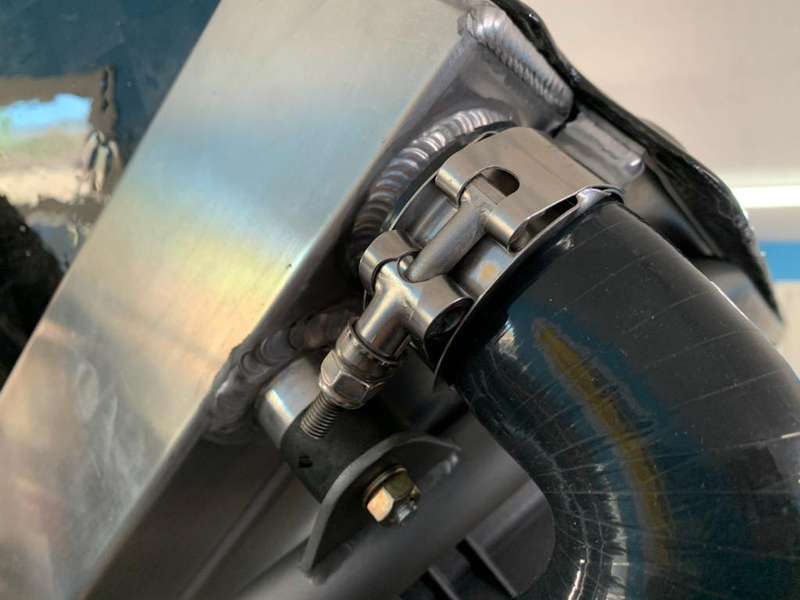

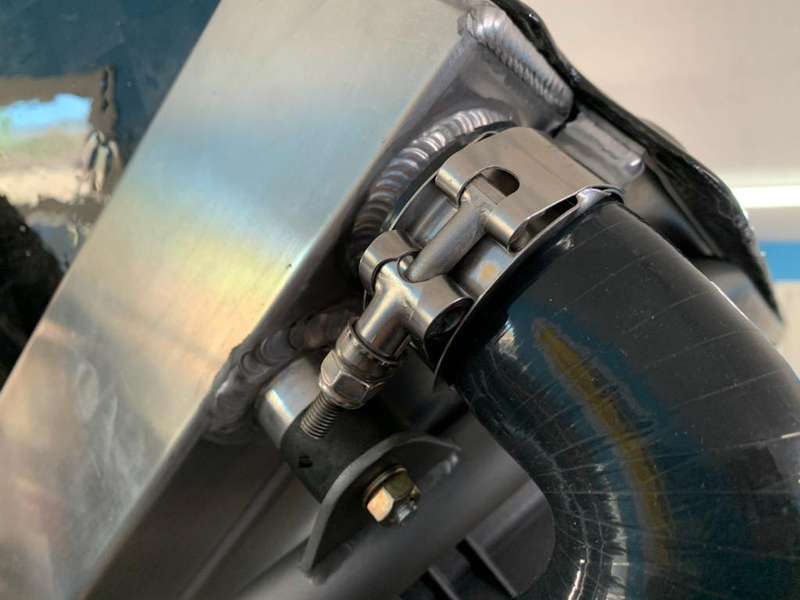

"T bolt" clamps installed

We had several different options for securing the cooling

hoses to the radiator and engine; "crimp" clamps, "hose" clamps

and "T bolt" clamps. We want the system to be serviceable

in the field so "crimp" clamps are out of consideration.

"Hose" clamps are easy but they tear up hoses and look cheap.

"T bolt" clamps are the most secure option and they don't tear

up the hoses - that's why we chose them. The only

down-side is that they're expensive. Fortunately, we only

needed a total of eight...

|