|

We've installed our

Fortin 2.5 power rack and attached the tie rods we fabricated a

while back; now we need to connect the steering rack to the

power steering control valve and the steering wheel.

That'll require a little problem solving and fabrication; the

problem solving involves routing the steering shaft from a

steering wheel comfortably located for the driver, past the

brake pedal without interfering with it, to the control valve

and then to the power rack. Along the way, we had to

fabricate and install bushings for the provided steering column

mount and also need to fabricate and install a mount for the

steering control valve. Simple enough but we really need

the brake and clutch pedal assemblies installed to insure

the steering shaft doesn't interfere with them. The

chassis is set up to

use CNC brake and clutch pedals; even though CNC closed up shop,

we were able to find the correct pedals in stock at McKenzies -

our favorite off-road supplier. We now have all the

steering and pedal components on order; once they arrive, we'll

get to work fabricating the remaining steering system elements.

Installing our Fortin 2.5 Power Rack

We still need to replace the hydraulic fittings with 90

degree elbows - we have the correct fittings but we need to

remove the rack from the chassis to install them...

Tie Rods installed and roughly adjusted

We also fabricated an identical spare to carry strapped to

the chassis

The steering column assembly, now ready to install

The above tubular weldment was supplied with the chassis, we

built it into to a "steering column assembly" with the

fabrication/installation of bronze bushings, set screws,

collars and a universal joint. This assembly can either be

welded or clamped to the chassis in our desired location and

orientation. We left the steering wheel end of the shaft long

for now so we can trim it to

length for driver comfort (once we determine where

that location is). We'll mount the brake pedal and

steering column assembly then locate and mount the control

valve. Once that's in position, we can fabricate the remainder of the

steering shaft.

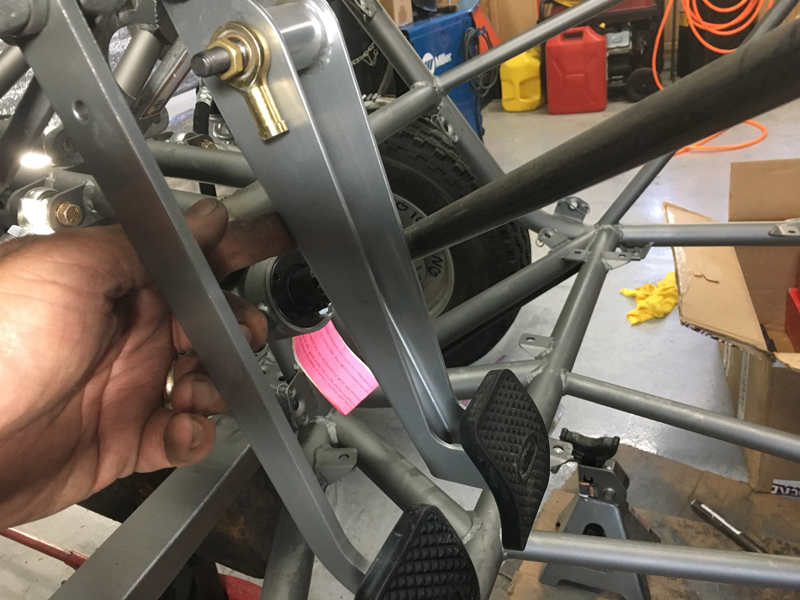

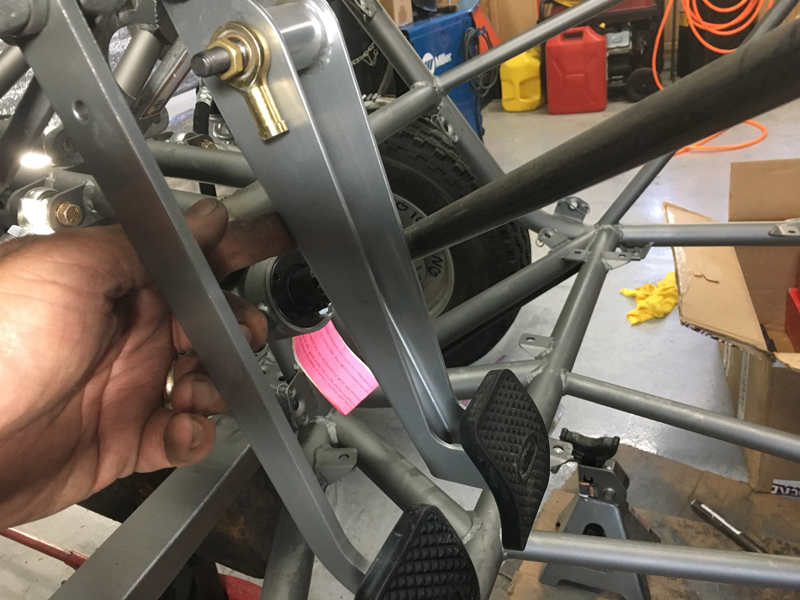

Checking the routing of the steering shaft

for Brake Pedal clearance

We spent at least an hour looking at various mounting

locations for the steering control valve; we were looking for

the best compromise between all the many factors - minimizing

universal joint angles, making sure that we could actually

install and remove the valve without cutting anything, ensuring

that there was room for the hydraulic lines, that there was no

interference with the pedals, etc.. We've seen other

examples of this car that have the control valve mounted a

little higher than the location we settled on - we really didn't

like the u-joint angles between the control valve and steering

rack that resulted when we mocked that up.....

Steering wheel and shaft mounted

We borrowed a seat from our 5/1600 car so we could

simulate the driver's seating location while deciding where the

steering wheel should be located both left-right and

forward-aft. The camera angle distorts the perspective -

the wheel was directly in front of the driver with the seat in

the correct location. Trevor says that the location we

settled on is perfect. You can see the universal joint

angle here is fairly mild - the steering wheel/control valve

shaft operates smoothly without slop. We'll install the

steering column mount more securely than shown here once we are

absolutely sure we like how it's positioned.

Universal joints welded on a

steering shaft section

After determining the correct length for the steering wheel

column/control valve shaft, we welded the universal joints in

place. We wrap the joints in a wet rag while welding so

that we don't overheat and ruin them. We didn't make the

control valve/rack shaft this day; the fit of the rack end

universal needs some finessing first... We need to remove the

rack anyway to install the correct hydraulic fittings so that'll

be on our list of things to do next time.

Final steering shaft section fabricated and

installed

Steering control valve and shafts installed

This photo is a little deceptive - the brake pedal is well

clear of the control valve and does not interfere throughout

it's entire range of travel. The pedals are "hanging"

about where they'll "bottom-out" the master cylinders. The

throttle pedal will be installed later and will also have plenty

of clearance. Other examples of this car place the control

valve on the top of the tubular member; we chose to locate it on

the bottom of the same member to improve the steering shaft

universal joint angles after investigating the potential points

of interference. We're very happy with the installation;

it's "slop free", smooth and secure.

Foot well area sheet metal trimmed to fit

around control valve

Brake and clutch master cylinders installed

With the master cylinders installed, we were able to

adjust the push rods to get the pedal positions we wanted and to

verify that full travel is available without interference of any

sort (it looks tight but there's plenty of room for my big feet

without coming anywhere near the steering shaft or valve).

Now that the master cylinders are installed, we can begin

installing the brake and clutch lines. The clutch line is

easy - no light switches or residual valves. The brakes

are a bit more complicated; we need a "residual valve" on the

rear brakes and we want brake light switches on both the front

and rear brake circuits. The turning brake unit will also

need to be mounted and have lines routed to it and from it to

both the left and right rear brakes separately.

Clutch pedal "stop" installed

It's important to limit the clutch pedal travel to avoid

over-actuating the clutch pressure plate and thereby damaging

it. We machined this assembly to act as an adjustable

stop; it replaces the nut securing the clutch master cylinder to

the pedal assembly and is easily adjusted as required.

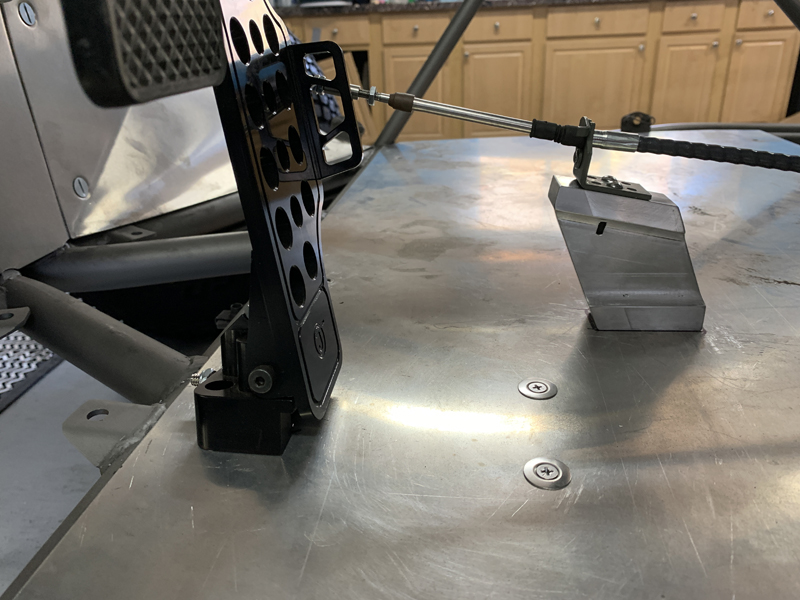

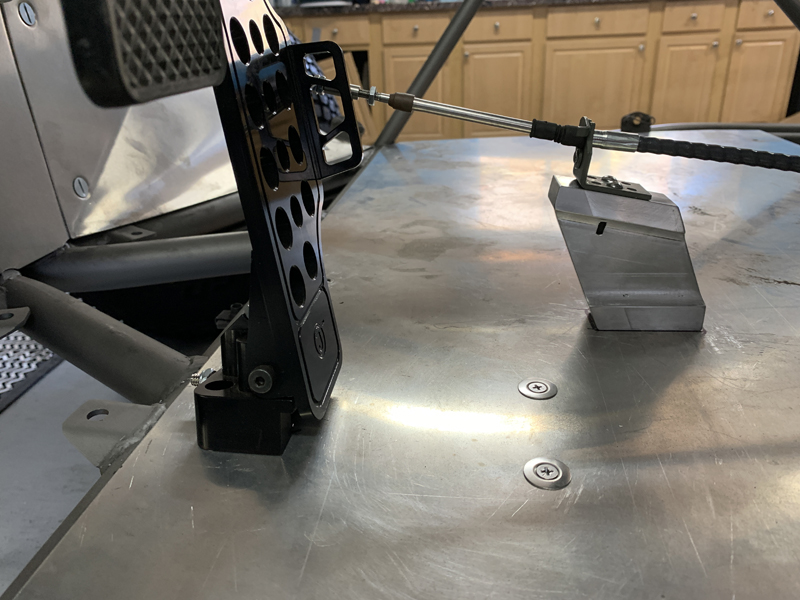

Accelerator Pedal and Throttle Cable

The gas pedal is a commercially available unit but the

throttle cable mount isn't. We milled the mount from an

aluminum plate after making a template to insure the shape and

location were correct.

Driver's seat installed on "sliders"

We wanted the driver's seat to accommodate drivers of

varying size so a "slider mount" was needed. We chose the

"towel bar" style slider rather than the "side lever" type for a

number of reasons, including ease of adjustment and security.

The photo is deceptive - there is 1 1/2" clearance between the

seat and the center "tunnel".

Passenger side slider base installed

We installed an identical slider base for the co-driver -

it's not absolutely necessary but it might make it more

comfortable for the co-driver.

|