|

With the car mechanically complete, the final stage of this project was to get the ECU programmed and the engine running. We built the engine to "race" standards in the hope that it would serve us well in our "lower demand" application. There are a few "experimental" aspects to the build however (dry sump conversion for one)... We did have some problems to solve along the way that required a fair bit of research and engineering. As noted above, the entire "dry sump" oiling system was our own design and construction. We initially had problems with the system feeding oil to the engine faster than it would "scavenge" at high RPM's. That could lead to eventual "oil starvation" if we were to run it too long above about 4000 rpm. Knowing that this engine was going to make it's best power between 3500 and 5500 rpm, that was a big problem. We began by taking the oil pump apart to check that it was in good condition - we discovered that it was missing seals and hadn't been assembled correctly by whomever had it before us. After re-assembling the pump with all the correct parts, the problem persisted. After much research, we finally solved the problem with the fabrication and installation of a custom "windage tray" and re-purposing the stock oil pump to function as an additional scavenge pump. Now, the oil level in the tank remains essentially constant throughout the entire rpm range. An additional issue was premature camshaft and lifter failures. Within the first few hours of running, several cam lobes failed, destroying their associated lifters as well. We believe this was the result of improperly heat treated "overhauled" camshafts. We had sent cores out to be reconditioned and were not happy with the initial results; we returned them to be reworked and were still not happy with the results the second time. Nevertheless, we relied on the assurances of the vendor and installed them only to have them fail quickly. That was a painful and expensive lesson. We ultimately purchased new manufacture "billet" camshafts from a European vendor - no U.S. vendors were found for these. The new cams were "manufactured to order" items so there was a several week wait for them to arrive. Once they did arrive, we were very happy with the quality. Fortunately, the EG33 engine is an "overhead cam" design so cam replacement doesn't require total disassembly of the engine; we were able to install them with the engine still mounted in the car.

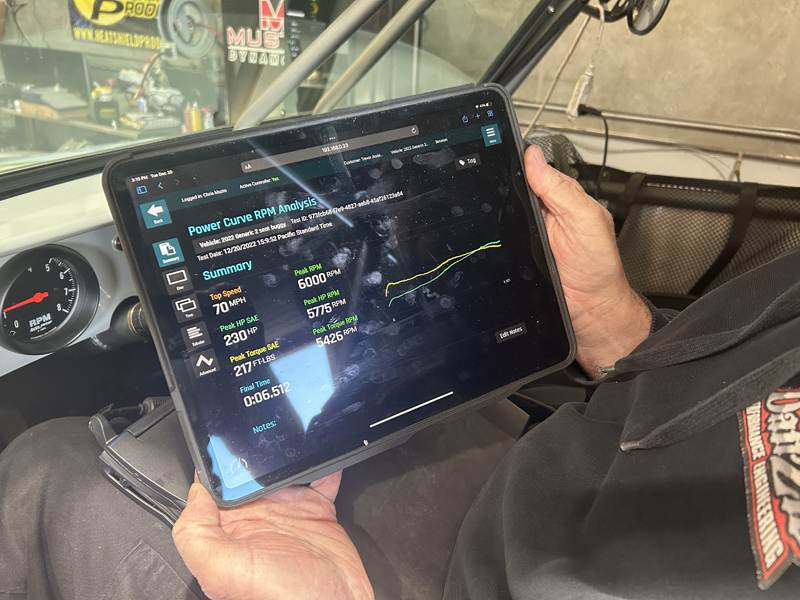

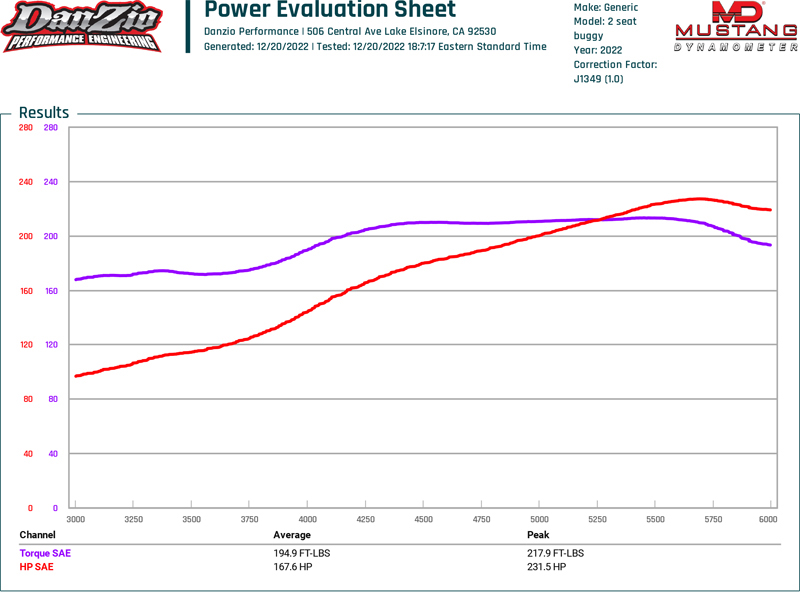

With those "speed bumps" resolved, it was time to head back to DanZio Performance Engineering to complete the tuning of our engine!

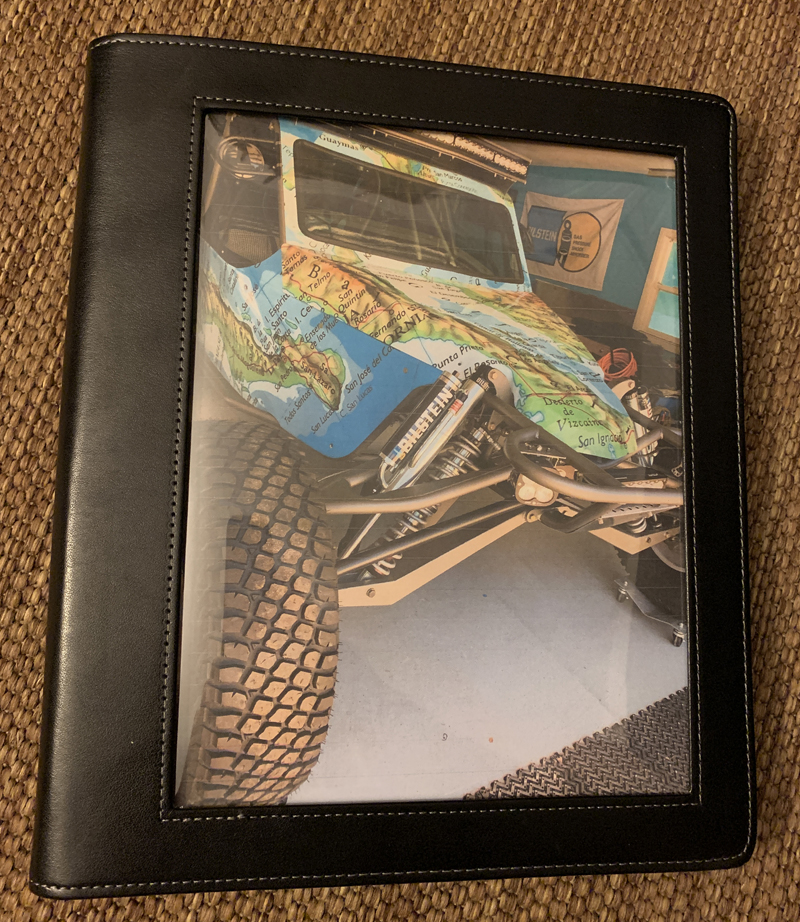

Documentation We've worked hard to document the pre-runner systems along the way; we created a comprehensive "manual" that includes wiring diagrams, plumbing diagrams, component installation manuals, etc.. Hopefully, if we ever need to work on any of the systems, it'll make things easier to sort out for us or whomever owns the car later.

This has been another

enjoyable and challenging family project that has kept us

busy for the last several years. We'll cherish the

memories and hope to enjoy the fruits of our efforts with family

and friends for many years to come!

A huge

thank you to our understanding, supportive and patient wives!

|