|

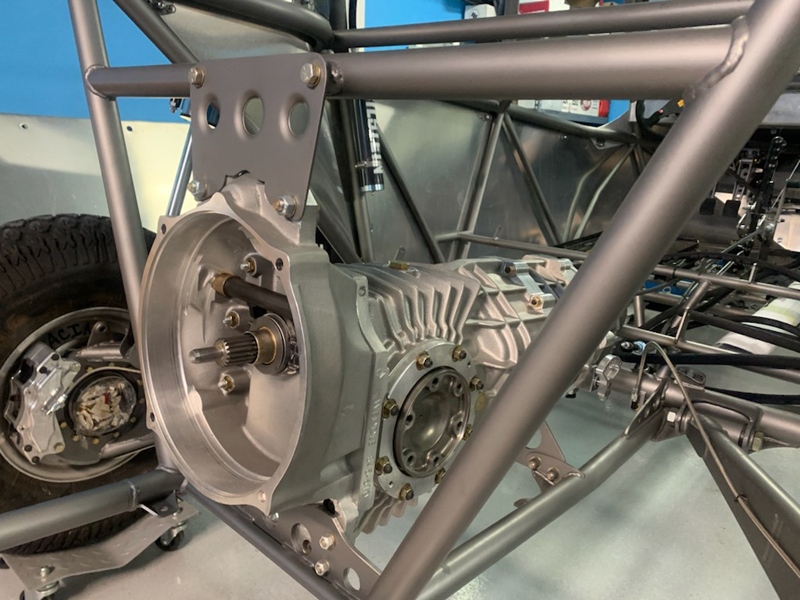

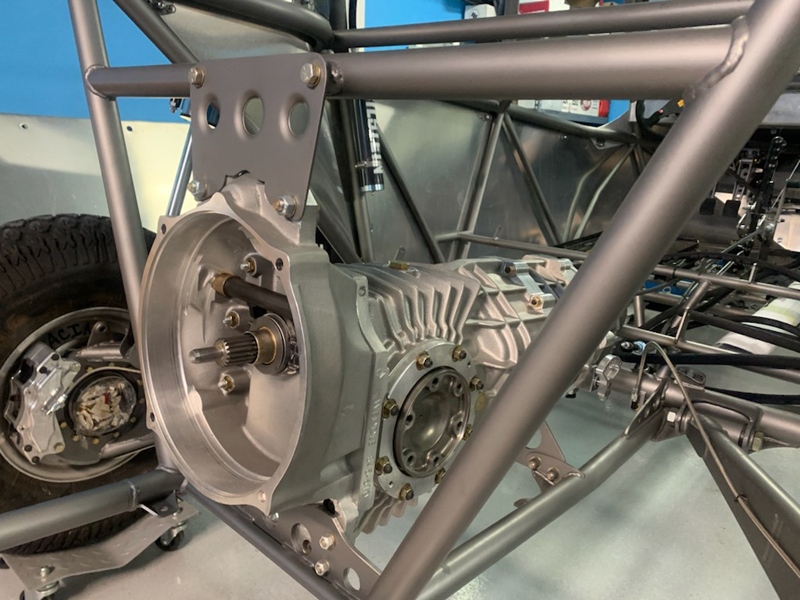

The transaxle is the biggest single expense

in the build (aside from the chassis itself) so we needed to

budget and save for it... The build finally reached the

point where we could go no further without it so we had "Power

Box" (Rick St.John at Hugo's European in Encinitas, CA.) build

us a new "Weddle S5" sequential transaxle. Rick has taken

care of our 5/1600 transmission since our first few races; he's

really good and a friend - that made asking him do the build an

easy choice! The current "Covid 19" pandemic has affected

production and availability with wait times in excess of 6

months in some cases. Rick really came through for us and

we had our transaxle within two weeks of giving him the "Go

Ahead"! We can't thank Rick enough!

Rick and our Weddle S5

We've never had a sequential transaxle previously so Rick

was kind enough to spend time answering our many questions.

The old guy on the right is me...

It's almost too pretty to put in a desert

car...

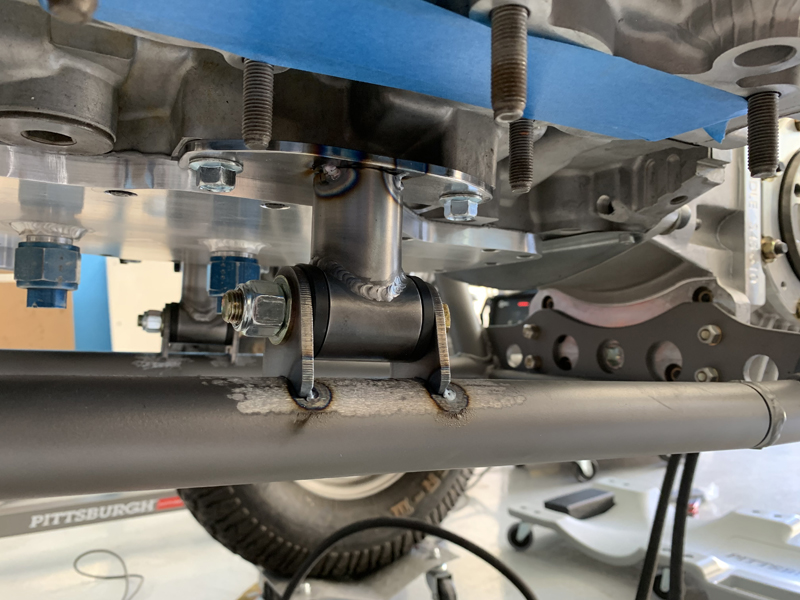

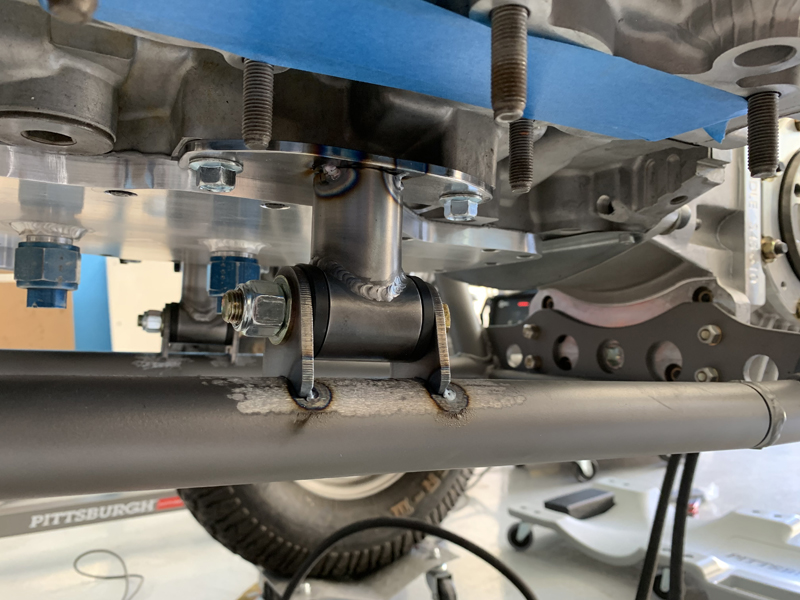

Bolted in to the chassis

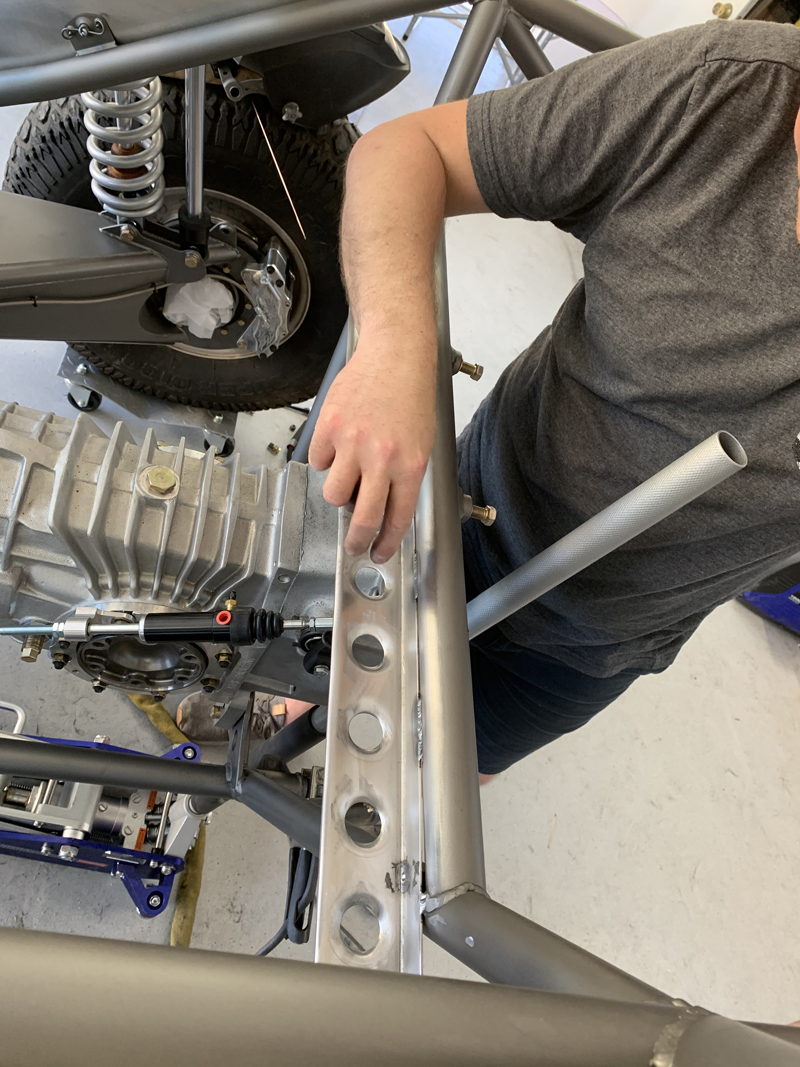

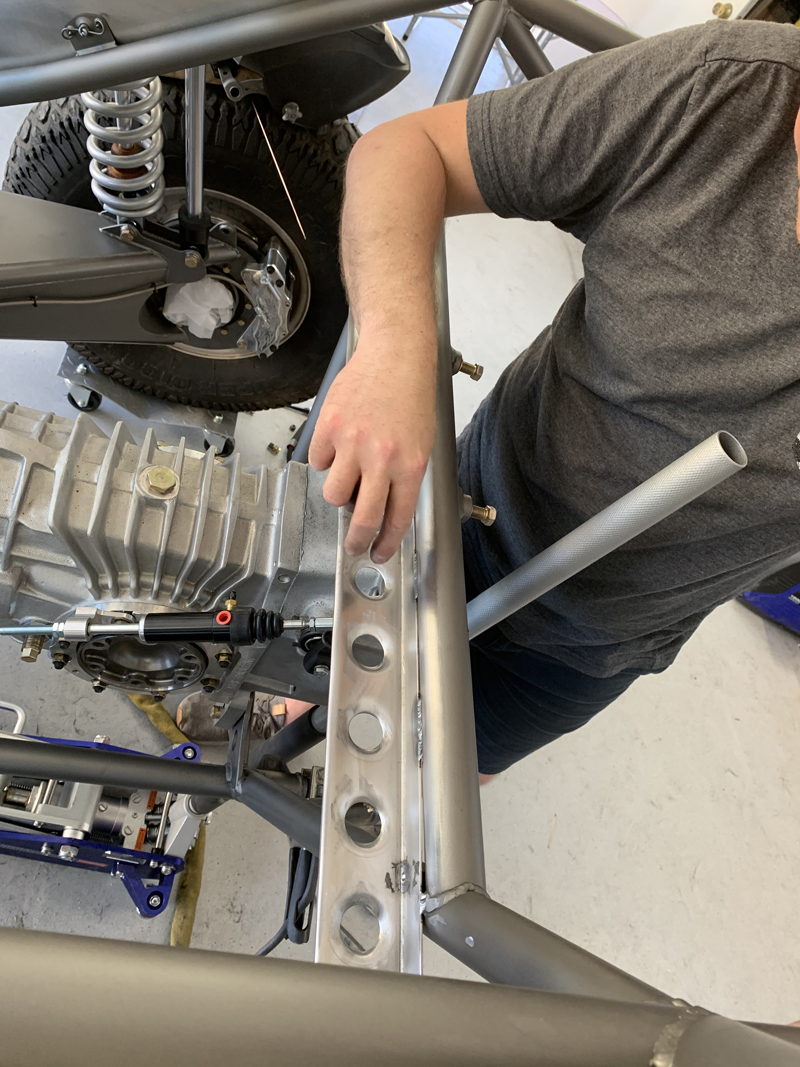

Trevor wasted no time getting the

transaxle bolted into the chassis. We have lots to do now;

shifter hook-ups, clutch slave cylinder installation, CV and

axle selection/purchase/installation, gear position indicator

installation, etc. There are many other things we can work

on now; engine installation, fuel cell installation, radiator

installation, plumbing, electrical, exhaust, etc..

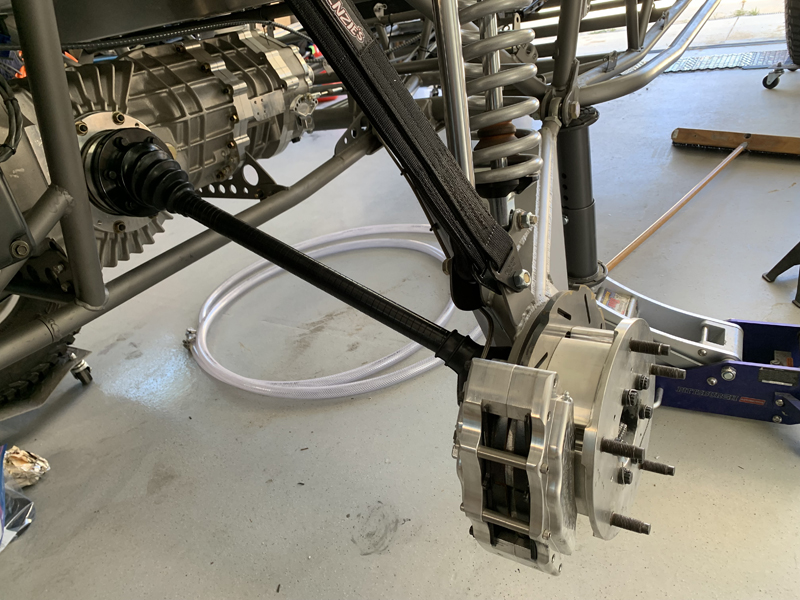

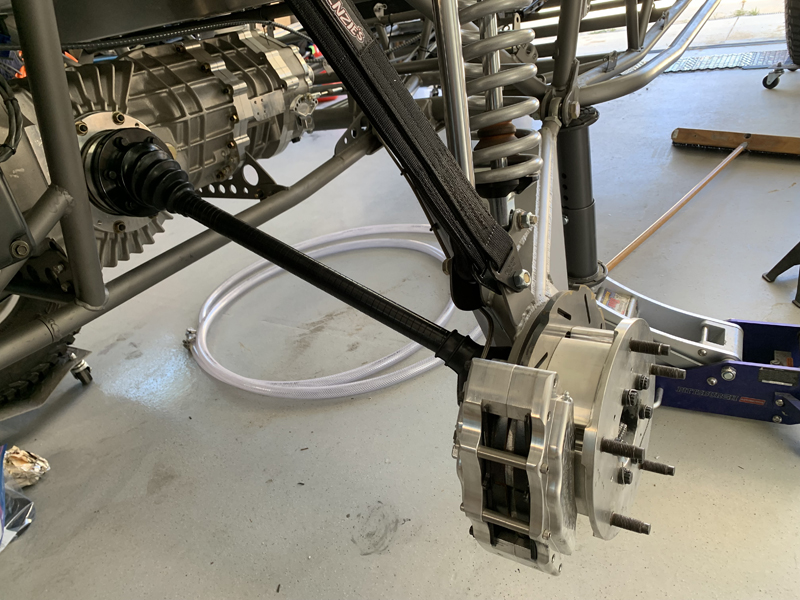

Transaxle 934 CV greased

Both the transaxle CV's and Mid-Board hub CV's were fully

greased during axle installation; hopefully they'll be happy for

many outings before we have to service them!

Axles, CV's and Limit Straps installed

Drive line fully complete now. We have our limit

straps set to allow no more than 24 degrees of CV angle

presently - we have the ability to increase or decrease that

easily. At this deflection limit, everything rotates

freely without any binding and the CV's should be "safe".

The CV's can probably permit a little more suspension travel but

we're being conservative - we can't really replace a broken

Mid-Board CV in the field...

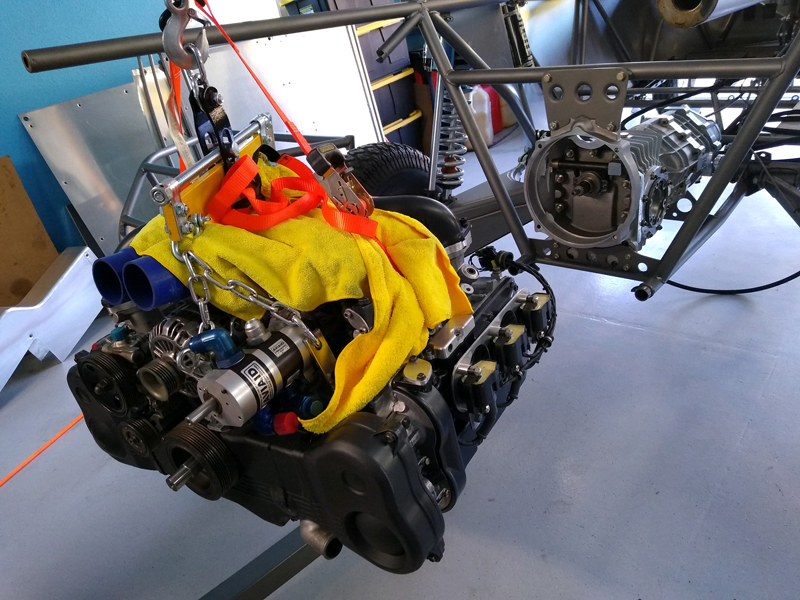

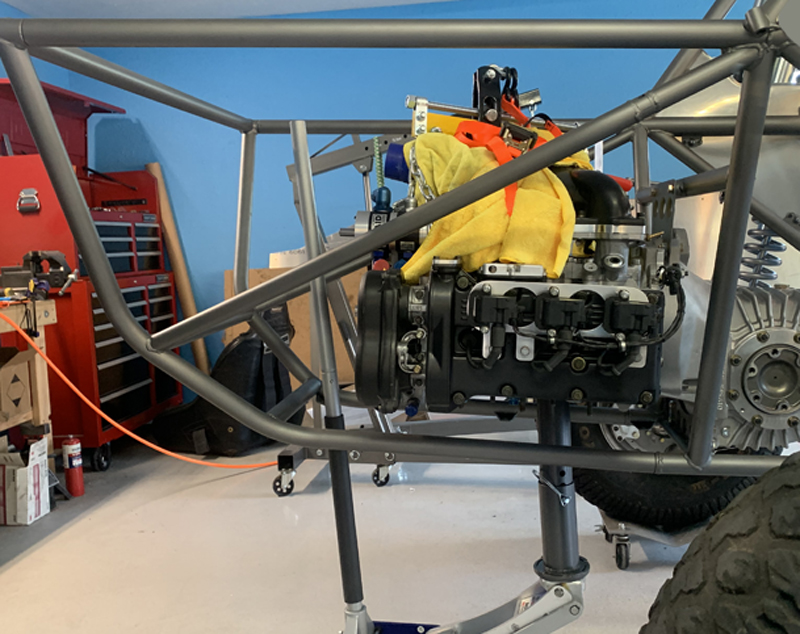

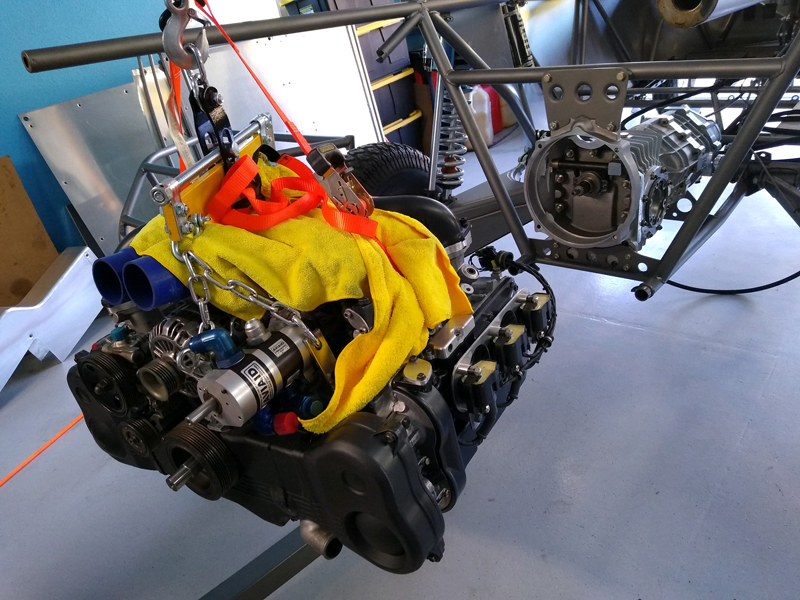

Hoisting the engine onto the transaxle

Engine bolted up to the transaxle

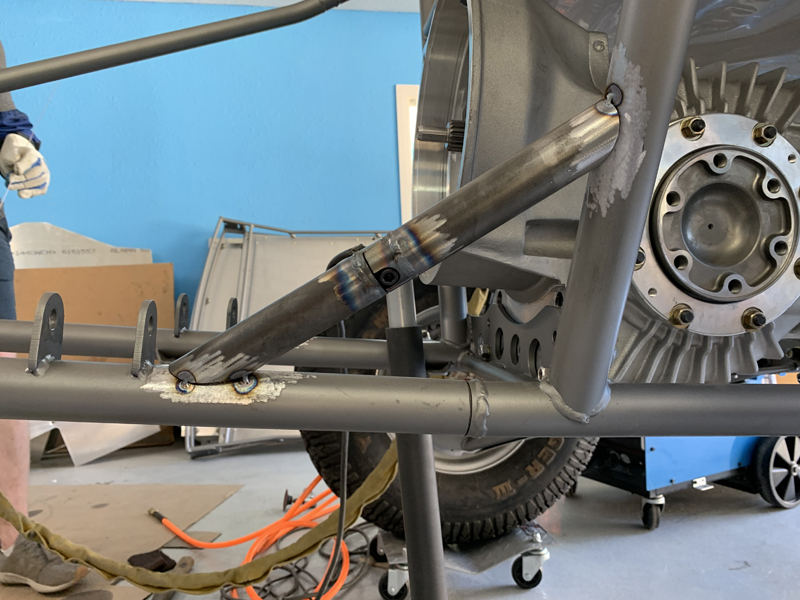

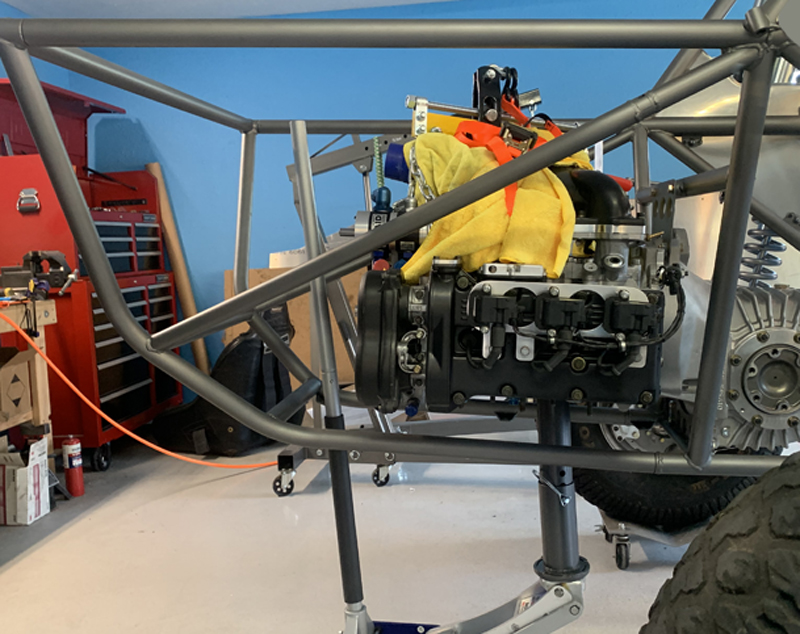

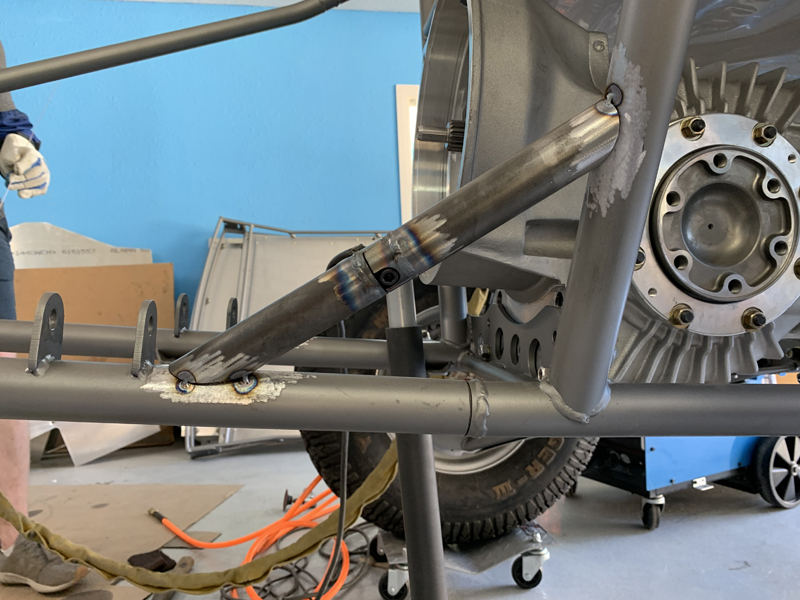

Fabricating engine mounts

We didn't want to rely solely on the transaxle for engine

mounting so Trevor fabricated a pair of these mounts.

We'll add a diagonal support tube in order to stiffen the mount.

Passenger side diagonal support tube tacked

in place

The support tubes were fitted while the engine was installed

to ensure a good fit. With the engine removed, they were

fully welded in place. As you can see, the supports have

"tube connectors" installed. While not ideal, we needed

them so that the rear cage structure remains "removable".

We felt it was important to add these supports because

otherwise, the engine mounts would transfer loads perpendicular

to the middle of a long, straight tube...

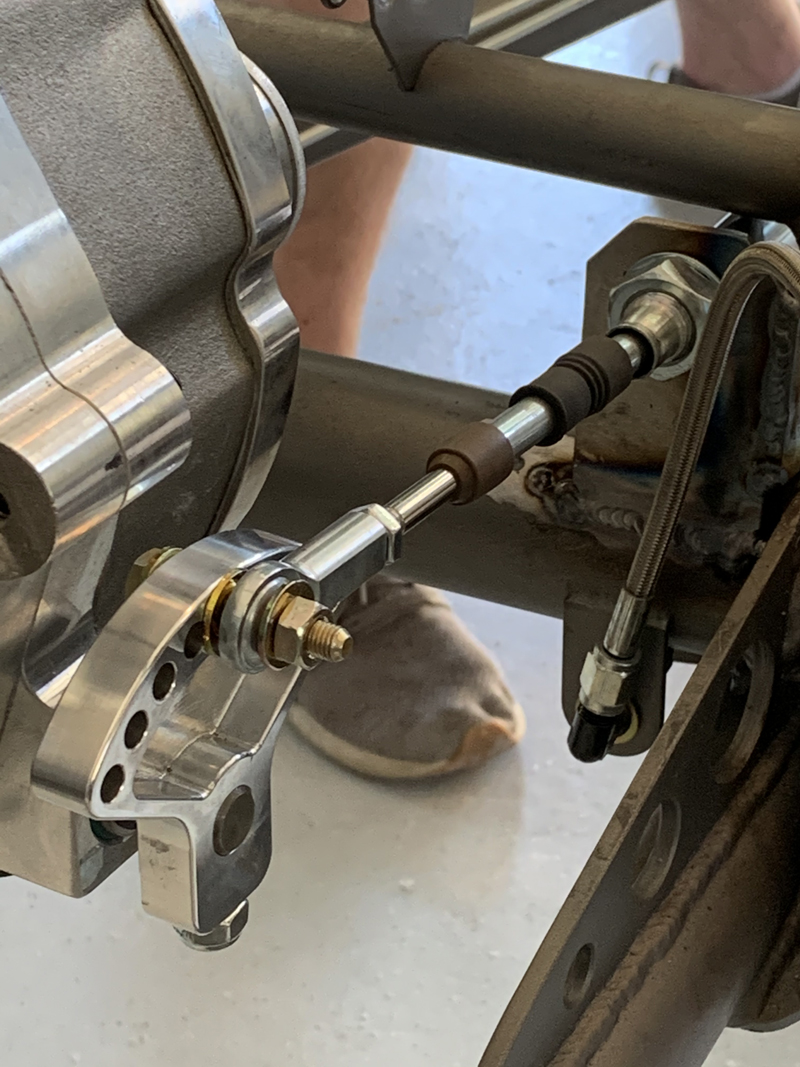

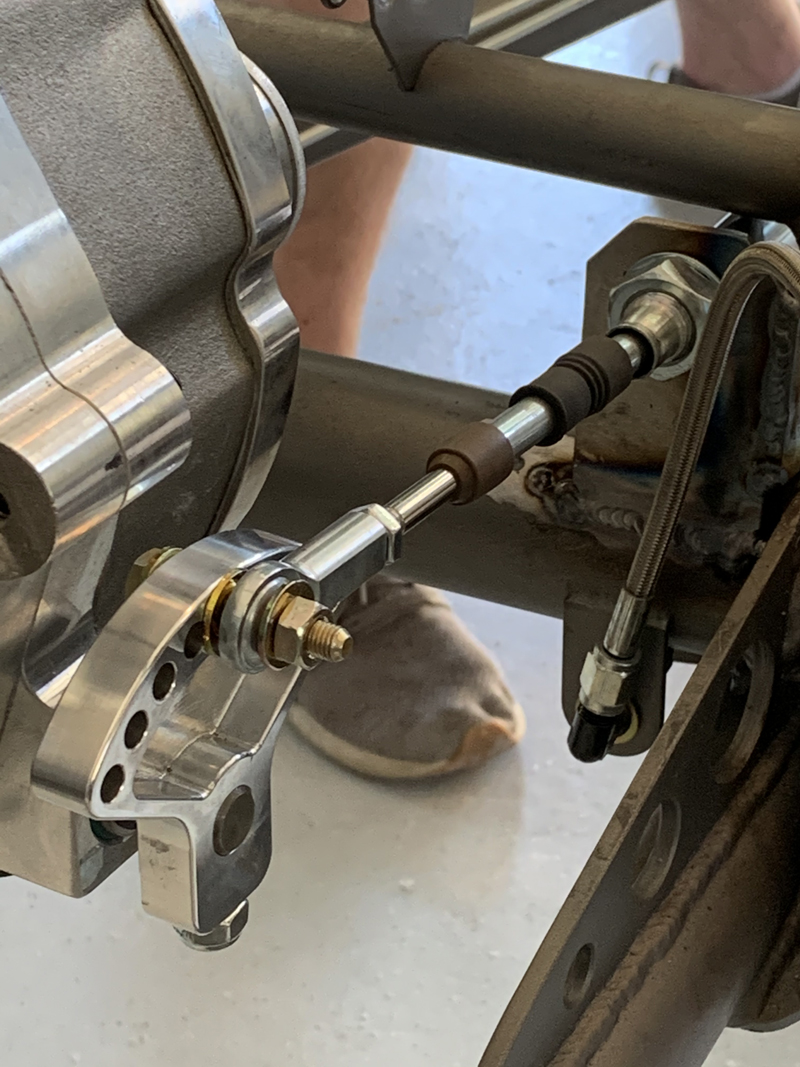

Shift cable mount fabricated and installed

Once both ends of the shift cable are secured, the shift

cable can be attached to the transaxle and the function of the

shifter tested. Shifting seems positive and normal at this

point. The "non-locking" nut securing the shift cable to

the transaxle is temporary; we'll replace it once the transaxle

is "final" mounted.

"Reverse" cable secured and attached to the

transaxle

As with the shifter cable, once the reverse cable housing

was secured at both ends, we were able to connect the cable to

the reverse lever and test the function of our shifter's reverse

lever - it worked perfectly. Again, the non-locking nut is

temporary.

Measuring for axle length

While at "full droop" (25

degrees CV angle) we measured the minimum "clip to clip" length

required to keep the axles from pulling on the CV stars.

While there, we also measured for limit strap length; the straps

will keep us from going beyond the CV's safe angular limits.

After measuring the minimum axle length (1/4" more than the clip

to clip length), we cycled the suspension to "mid-travel" to

measure the maximum allowable axle length. The maximum

axle length is limited by the drive flange at the transaxle and

the dust cap at the wheel's CV. We need axles that are

long enough to allow full droop without "pulling" on the CV

"stars" but not so long that they bind with the drive flange and

dust cap at mid-travel. The left and right sides were

slightly different but we'll be able to use a single length axle

for both sides without issue - 33 1/4".

Rear fuel cell mounting "tray"

This tray supports the rear of the fuel cell and is not

removable. The front supports will be removable to

facilitate initially getting the fuel cell into the space and

will then be installed under the cell. Yes, we know the

clutch slave cylinder isn't oriented with the bleeder valve "up"

at the moment....

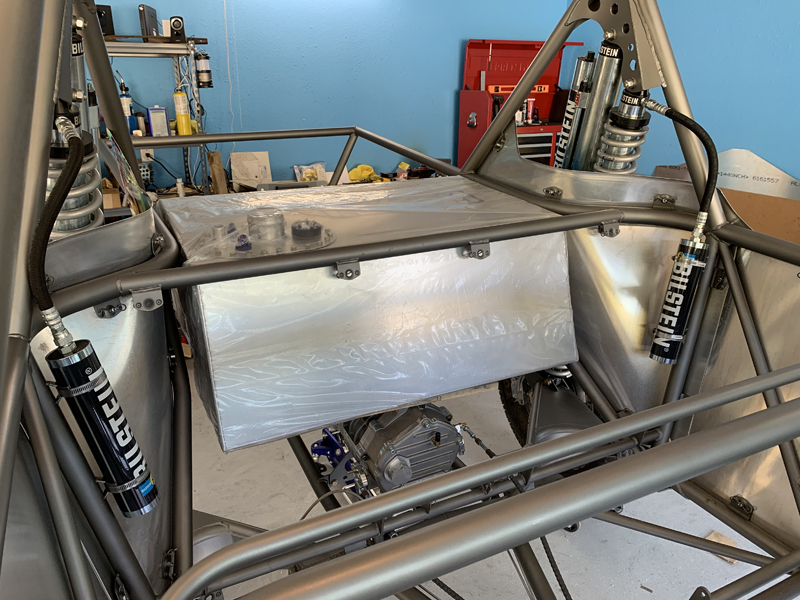

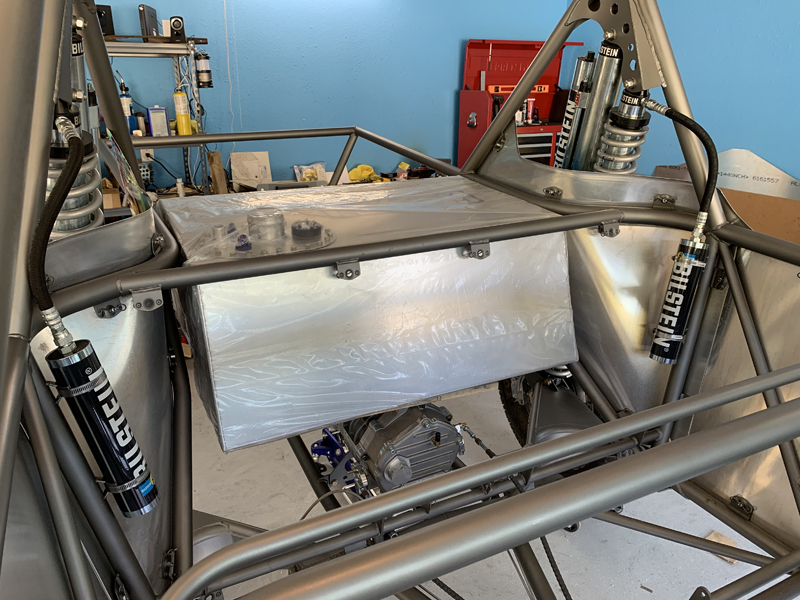

Fuel Cell mounting "mock-up"

The fuel cell is sitting on the rear tray but is supported

with temporary spacers between it and the transaxle so that it

sits at the correct height. We'll fabricate supports for

the front and middle of the fuel cell, ensuring that the loads

are distributed evenly. Those supports will be removable

to facilitate installation of both the transaxle and the fuel

cell. Once in place, the supports will be installed from

below and the fuel cell strapped down.

Fuel Cell location

The fuel cell resides above the transaxle and behind the

rear seats. It's a tight fit and the fuel cell supports

would also interfere with transaxle installation - that's why

they need to be removable. Our plan is to weld tabs to the

chassis that allow us to bolt the support structure under the

fuel cell once it's installed.

Fuel Cell support tubes

We fabricated two "cross tubes" that support

the fuel cell at the front and center locations in addition to

the rear "tray" visible here. To avoid "point loads" on

the fuel cell, we fabricated small "L" brackets and welded them

to the tubes - they help distribute the loads along the edges.

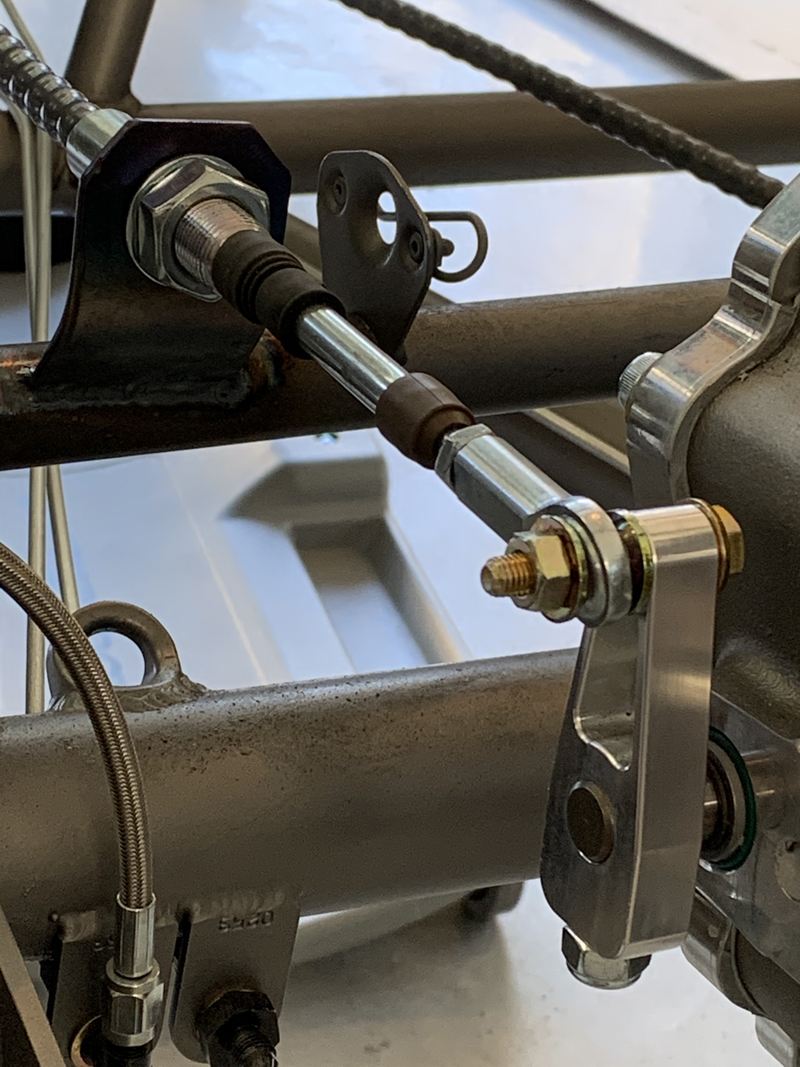

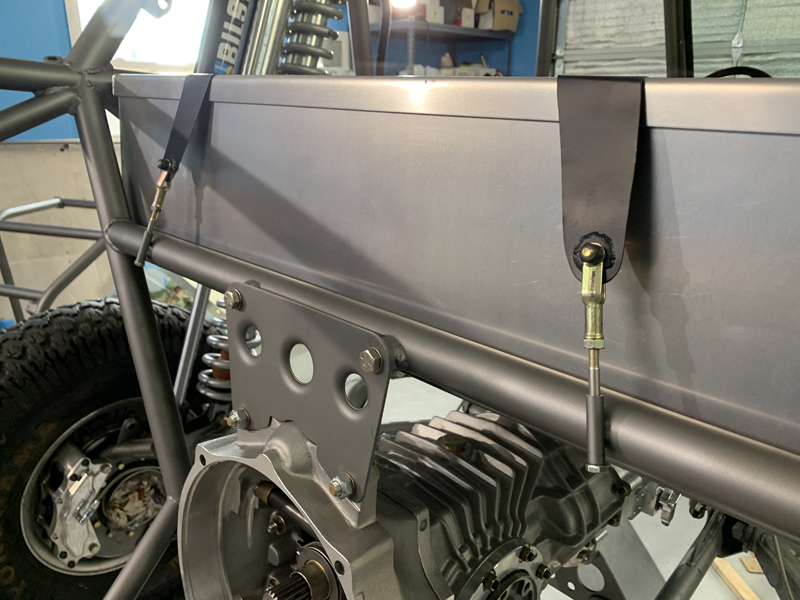

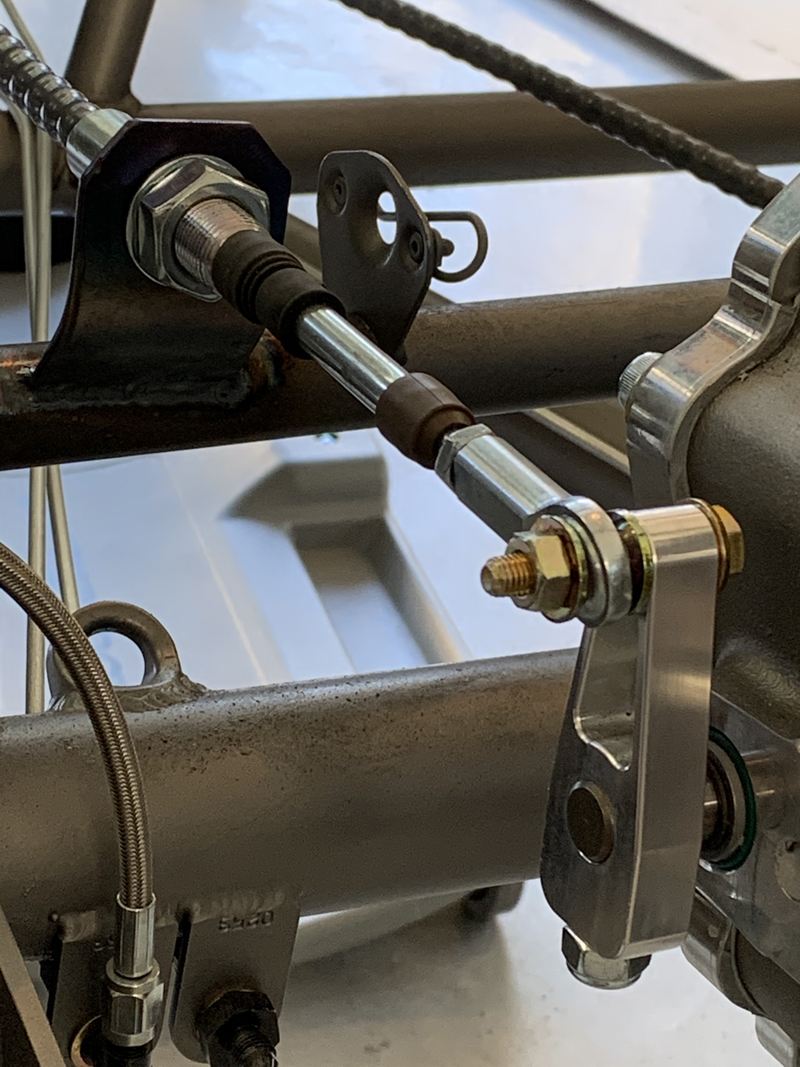

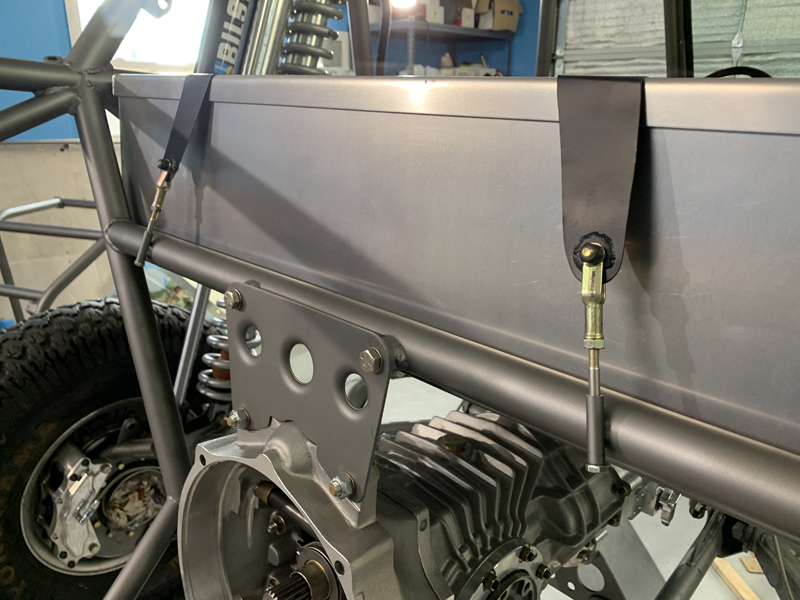

Fuel Cell "strapped down"

We fabricated 2" wide 4130 straps that bolt to the chassis

at the front and are tightened at the rear with clevis and bolt

assemblies. It's very secure but will be easy to remove.

You can see that the fuel cell is a tight fit between the upper

chassis tubes - we've installed leather strips between the tubes

and the fuel cell to reduce chaffing.

Clevis and Bolt Assemblies

These "clevis and bolt" assemblies allow us to

secure the rear of the retention straps and adjust the tension

in the straps as well.

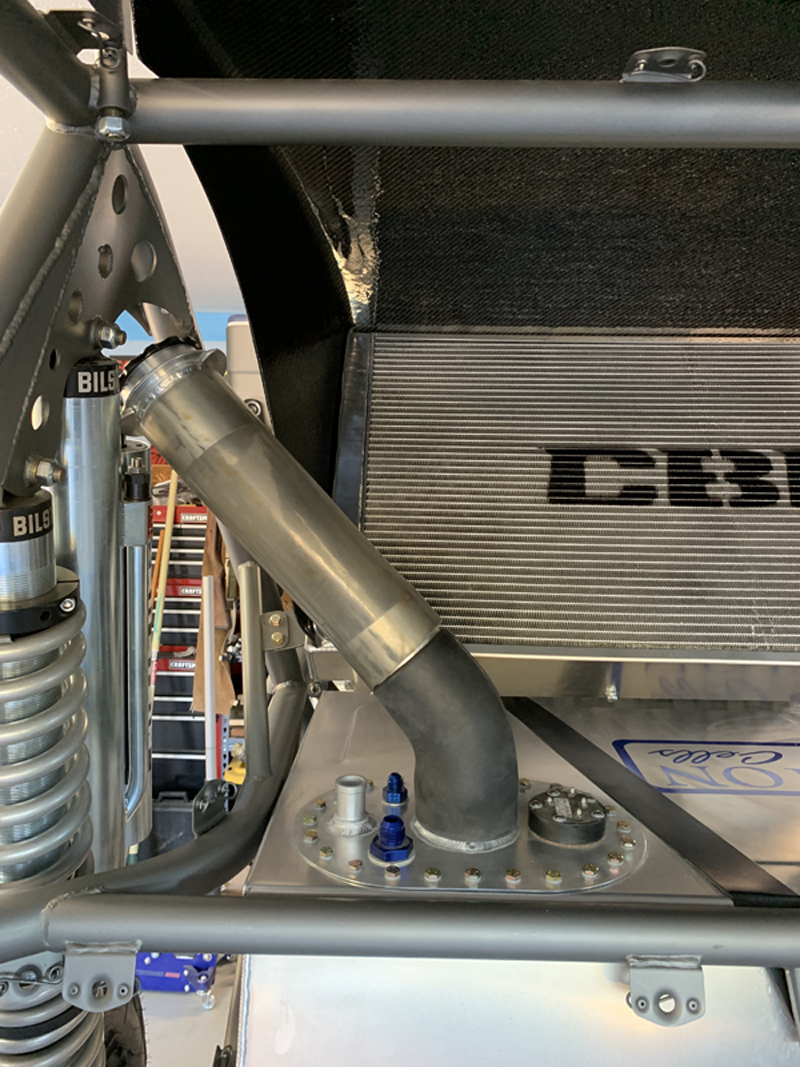

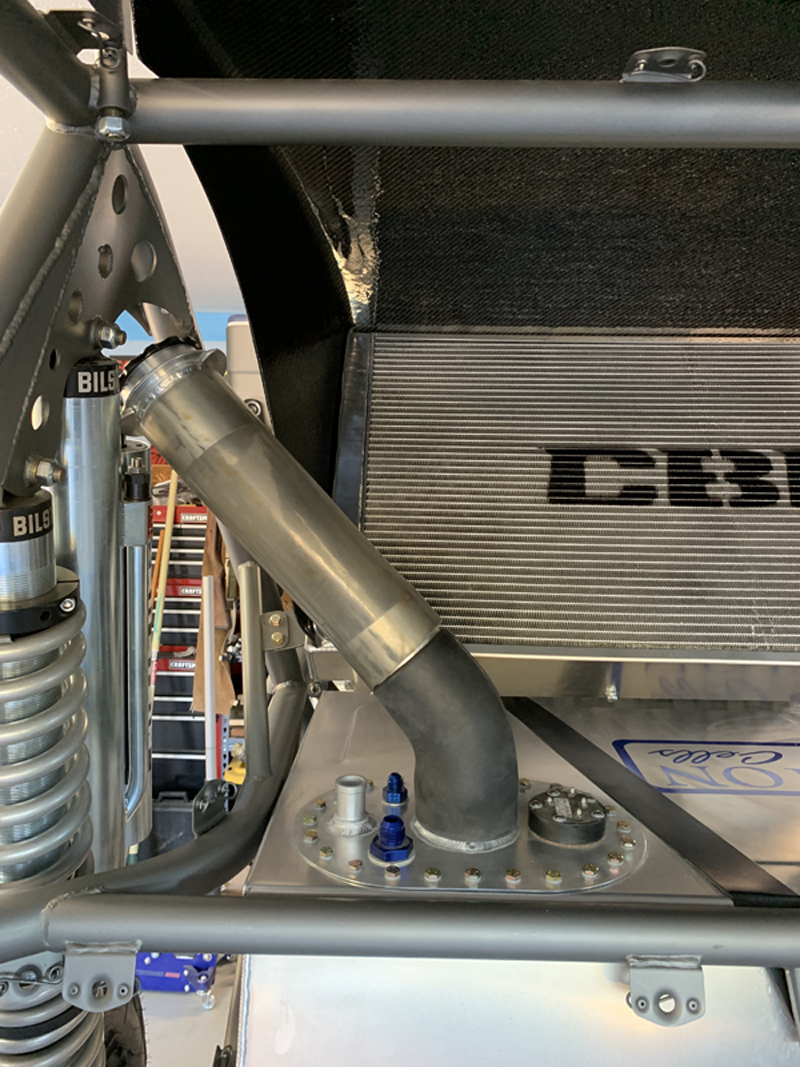

Fuel filler cap mounted

The fuel filler cap assembly is easily

accessible and remains clear of the shock as it cycles normally.

Fuel filler hose assembly fabricated

"Final" installing engine

With the fuel cell final installed, the transaxle and engine

could also be installed. With the engine and transaxle

finally in place, we can begin fabricating all the other details

- throttle cable, oil reservoir, air filters, power steering

reservoir, etc..

Fuel cell, engine and transaxle final

installed

All the major drive train components are installed now.

Still lots of work to do before the first run!

Supplemental engine mount

We didn't want all the weight of the engine supported by the

transaxle "bell housing" so Trevor fabricated these supplemental

mounts. Not wanting to apply a load in the middle of an

unsupported tube, we also added the diagonal you see here (one

on each side).

|