|

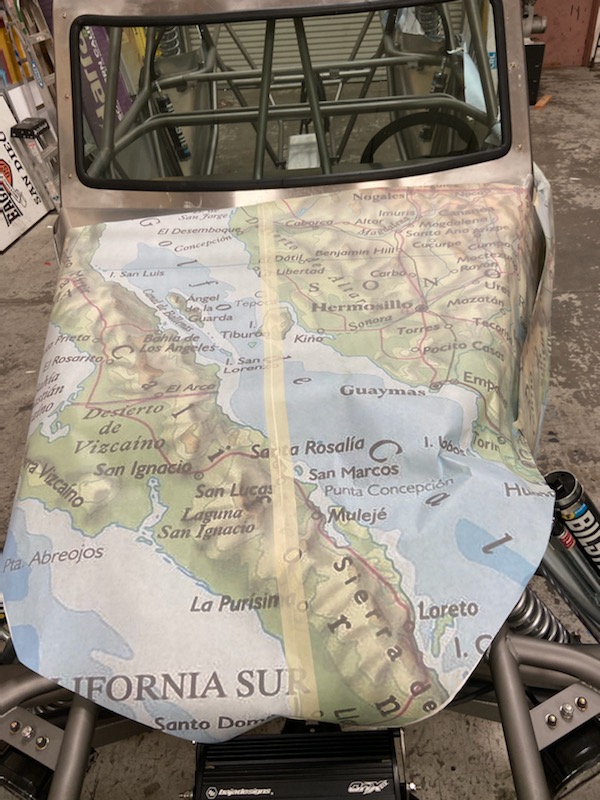

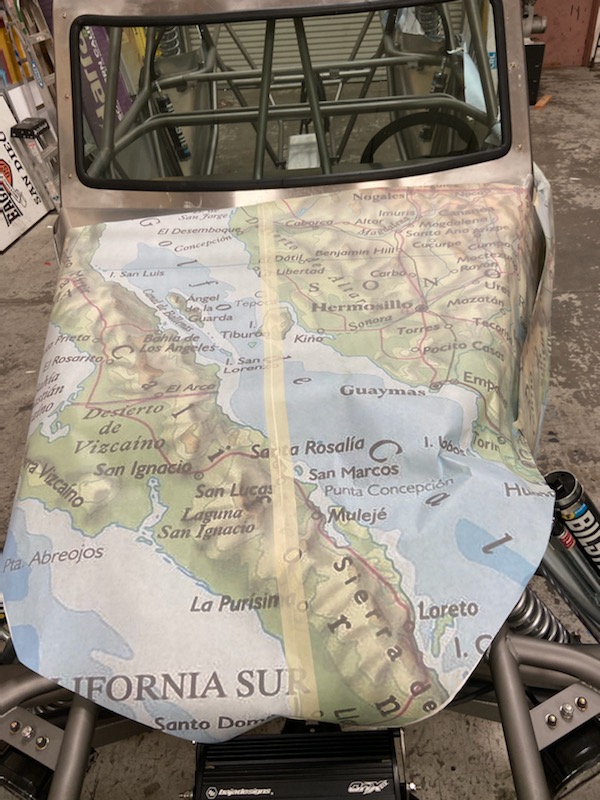

Chassis Wrap

The choice of the exterior finish was

something we discussed since the beginning of the build. A

simple paint finish would be fine but we wanted something a

little different... We've spent so much time in Baja

racing and vacationing that we wanted to do something to

commemorate all the adventures and great friendships we've had

along the way.

Bare chassis, ready for our wrap

All the sheet metal body panels installed after applying an "Alodine"

conversion process for corrosion protection. This process

includes an etch to remove surface oxidation then an immediate

application of the Alodine conversion coating to seal up the

surface. After the conversion process the final finish

process is applied over the top. Rather than paint, we

elected to apply a wrap that we were able to custom design.

Mocking up the hood wrap

Prior to printing the vinyl wrap, our vendor spent time with

paper prints to work out the fitment and overlaps. Given

that the map we wanted to use was of the Baja peninsula, some

artistic discretion was involved...

Mocking up the side wraps

We've worked with "CJ Norby Signs" in El Cajon, CA for many

years; it was an easy choice to have them do the wrap for us.

It was a long process of talking with Carol about our idea,

getting the artwork to her, having her design the final layout

and then having her apply the wrap. Carol did an

outstanding job for us at a great price!

Carol and Mark getting the car ready to

bring home

Trevor and I were stunned the first time we saw the wrap - it

really grabs your attention! The photo doesn't capture how

vibrant the colors are; it really "pops!"

Back home in the garage

Finally, back in the garage where we have control over it!

We still have chassis work to complete and we don't want to

damage the wrap so we removed all the panels to store them

safely. We'll leave them off until all the chassis work is

complete and we're ready to close it up for the last time.

Front view of the car

I really like this view of the car!

Just one more photo!

Window Nets

We chose to install window nets for

passenger safety; they are not required unless we race but

they're important safety items in the event of a roll-over.

The nets serve to keep flailing arms inside the chassis where

they're less likely to be crushed between the ground and

chassis... The nets are quickly removed with one hand when

necessary, either from inside or outside the car. Ours

were made by MasterCraft Safety from individual patterns that we

provided to them.

"Passenger side" Window Nets

The "driver side" nets are a mirror image of these.

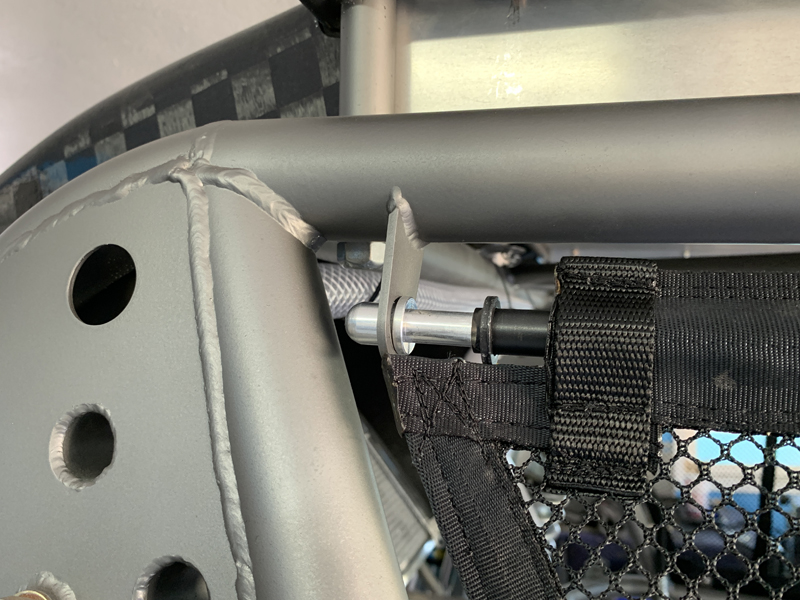

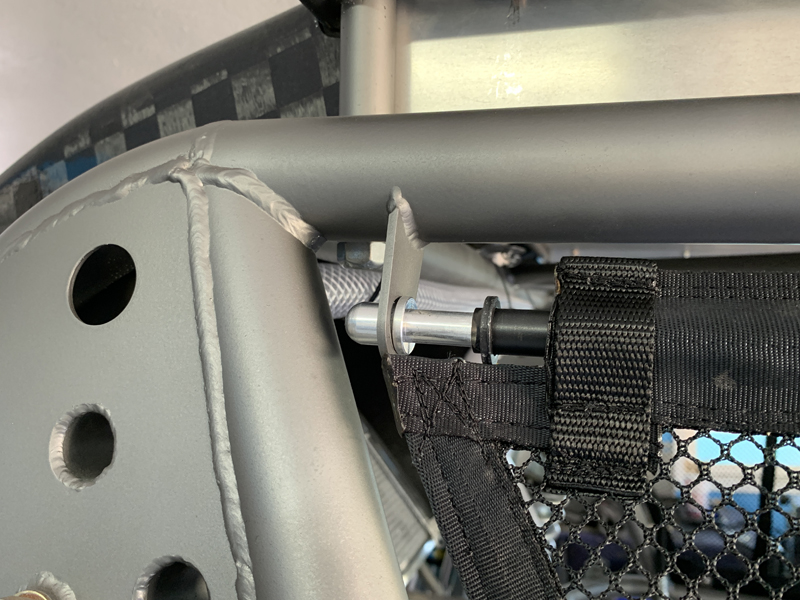

Upper Front Mount Tab

The upper support bar is spring loaded so that

it is retained in the window opening but is easily removed by

pulling rearward on the handle that protrudes into the passenger

area. The handle is barely visible through the net in this

photo.

Upper Rear Mount Tab

This is the "spring loaded" end of the

upper support bar - it allows the bar to slide rearward in order

to disengage the forward tab for removal of the window net.

The lower edges of the window nets are fixed to the chassis;

once the upper bar is removed from the tabs, the net is simply

"draped" over the side of the car to allow entry/exit.

Lower Window Net Fastener

We used stainless steel fastners to mount the window nets

and "Acorn Nuts" on the inside of the chassis so that there are

no sharp edges to catch as we get in or out of the car.

|