|

We've elected to fabricate and install the

electrical system ourselves for a number of reasons including

cost, time and the ability to create exactly what we want.

We have some experience in the subject and don't believe that

we'll regret this choice later...

We'll be using high quality components and

wire throughout and will endeavor to complete the job to a high

standard of durability, reliability and function. Some of

the work is already done for us; the engine came with a "Sakata"

harness tailored for it and a MoTec ECU. We'll only need

to plug all the connectors into the correct sensors and supply

power, ground and an ignition switch input. We chose to

purchase a "Switch Pros" 9100 - an eight circuit electronic

switch/relay/circuit breaker unit that eliminates the need for

us to create all those systems... We'll still be

responsible for all the basic things; radio, GPS, intercom,

lights, starter, etc..

"Reverse" micro switch

We mounted this micro switch to sense when the transaxle is

in reverse. Our rear tail light unit has white "back up"

lights that we want to use and the transaxle gear position

indicator can also display "R" when triggered to do so.

This micro switch will control a relay for the actual load

switching; it's own contacts aren't rated for the required

amperage but can easily control a relay for working loads.

Ignition switch wired

This photo is of the early stages of wiring the dash - we

still need to wire the instruments and "idiot lights". The

challenge is keeping it neat, orderly and secure while ensuring

that everything works as expected. The multi-conductor

wire visible is for the gear position display - we'll be

installing a 6-pin connector on it to mate to the cable that

comes from the "sender" mounted to the transaxle.

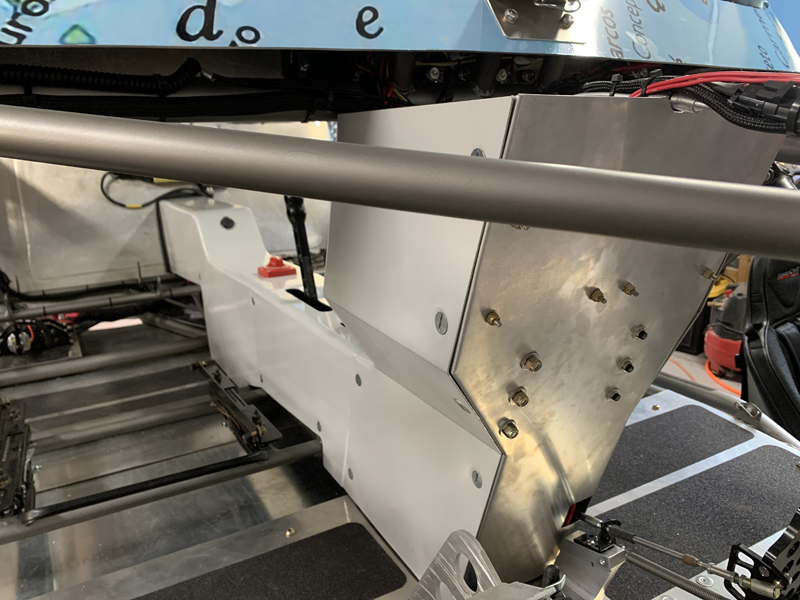

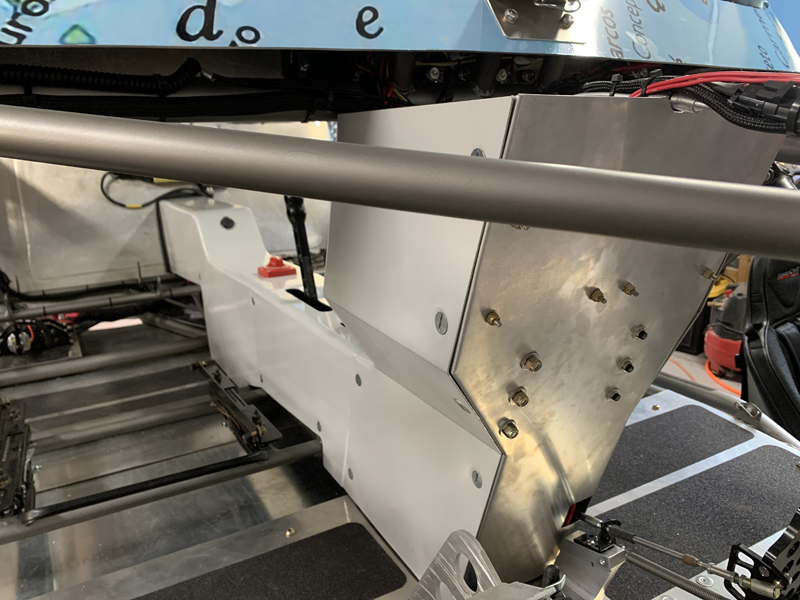

Center Console "Back" Panel

This panel closes out the center

console on the "back side" (towards the front of the car).

We've chosen to mount all the terminal strips, relays and

circuit breakers (aside from what's contained within the "Switch

Pros" unit) here for easy access and neatness. None of the

wire, relays or terminal strips will be visible once the center

tunnel and console are final installed; it'll still be easily

serviceable when necessary. We'll have a terminal strip

for the ignition "RUN" items, one for the ignition "ACC" items,

a "LIGHTS" bus and a "GROUND" bus. The circuit breakers

protect the powered buses and the relays are for the horns,

reverse (back up) light and manual control of the radiator fans.

The Switch Pros unit handles all the other switch, relay and

circuit protection requirements.

Center console back panel installed

With the back panel installed, all the bus bars, relays and

wires are contained inside the center console. This makes

for a tidy installation that's easily serviceable when

necessary. Visible are the three circuit breakers that

protect the "Run", "Acc" and "Starter" buses. All the

other circuits are protected by the "Switch-Pros SP9100" unit.

It takes the place of conventional switches, relays and circuit

breakers for up to eight individual circuits. We're using

only five of the eight circuits for now but plan to expand in

the future (fresh air pumpers, rock lights, etc.).

Oil Temperature Sender

All of the engine information "senders" are "one wire"

senders. Each sender has a single wire going to the

respective gage which also has power and ground connections

installed. The gear position indication system has a few

more wires to indicate reverse and for dimming the display when

the headlights are on.

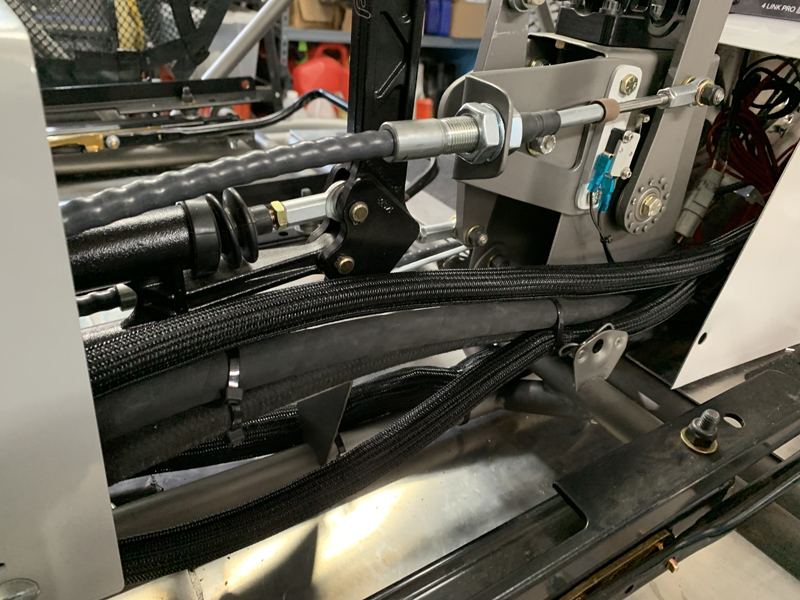

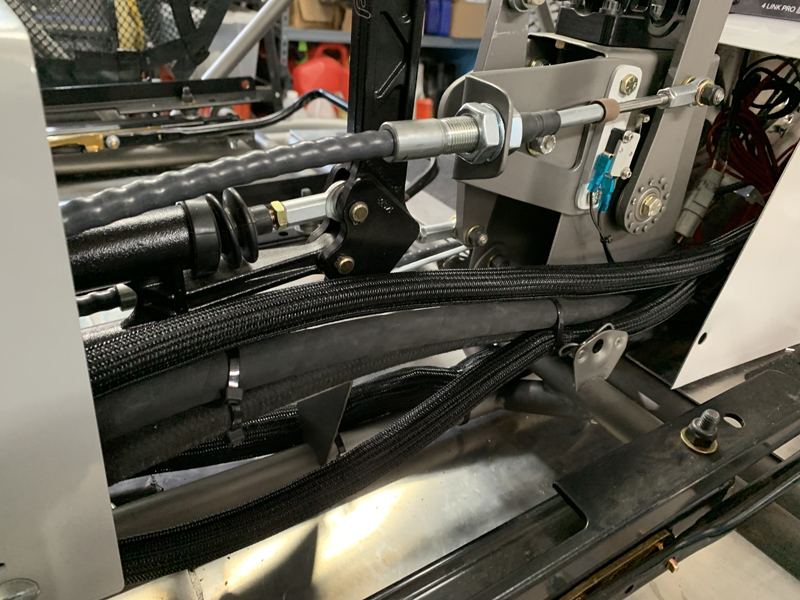

Protective sheathing on wire bundles

We did our best to protect and secure the wire

bundles for reliability and long life.

It's "Alive"!

Everything works as expected; all the lights, fans,

pumps, radios, instruments, etc.. We have only the horn buttons

remaining to be connected; we want to be able to remove the

steering wheel so we'll need to be able to disconnect the horn

button wires when we do so. We'll also need to provide for

the rotation of the steering wheel; we'll be using a coiled

cable to allow some "stretch". The coiled cable will be

fitted with a quick disconnect to allow for removal of the

steering wheel.

Removable steering wheel cable

We want the steering wheel to be removable from the

car for security reasons - that means that we need to be able to

disconnect the horn button wiring. We used a coiled,

multi-conductor cable to permit free movement of the steering

wheel while in use and installed a male helicopter headset plug

on the free end. The steering wheel has two buttons, wired

together in parallel for the horns. Our original

plan was to separate them to use one for the horns and the other

for a radio transmit button. We later chose to leave them

configured for horns only and mounted a dedicated radio transmit

button for the driver on the dash. We expect that the

co-driver will do most of the radio communications anyway.

Helicopter headset plug

The helicopter headset connector allows four

different wire connections to be made - we chose these because

our original plan was for the cable to carry both horn and radio

switch signals. Having decided to use the steering

wheel buttons for horns only, we'll now use only two of the four

contacts.

Horn cable installed and functional

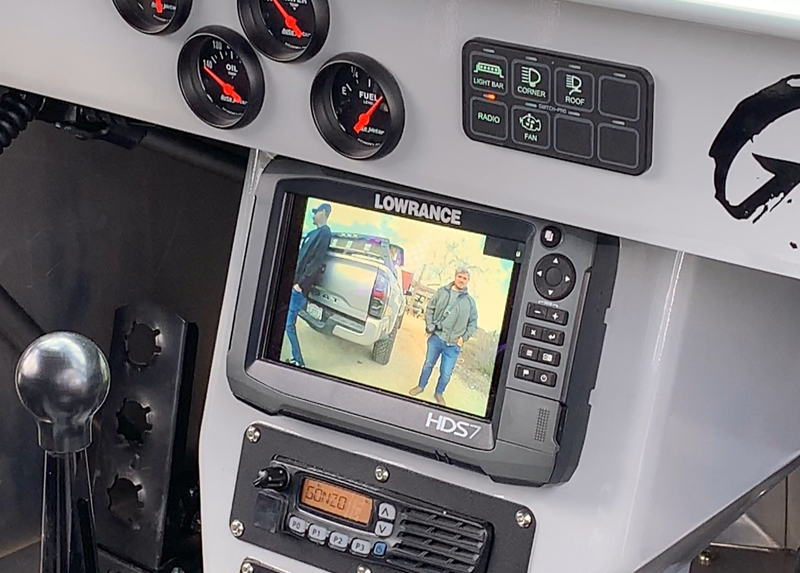

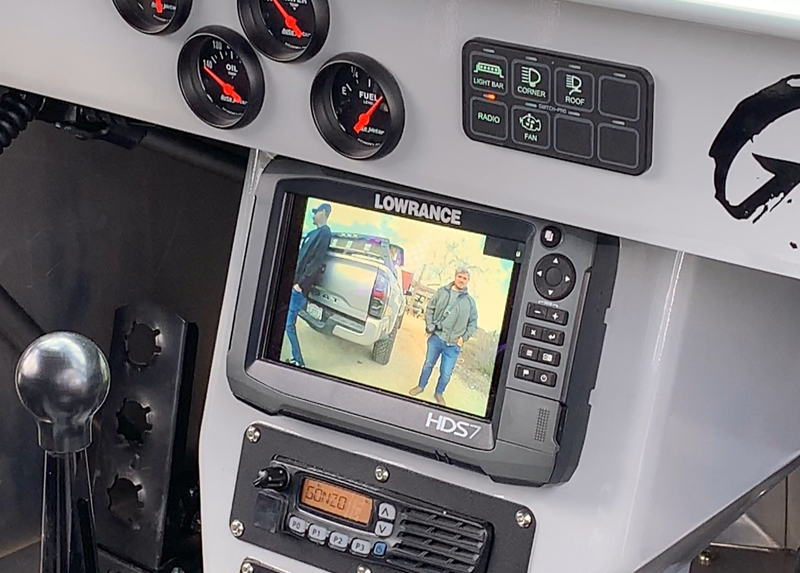

Rear view camera display on GPS

Due to the location of the radiator and spare tire, the

driver has no visibility directly behind the car.

Fortunately, our Lowrance HDS7 can display live video camera

images. We mounted a small wide angle camera on the rear

bumper and can display that view at any time by selecting it

through the GPS touch screen menu. Unfortunately, we can't

configure it to automatically switch to the rear camera view

when "reverse" is selected...

|