|

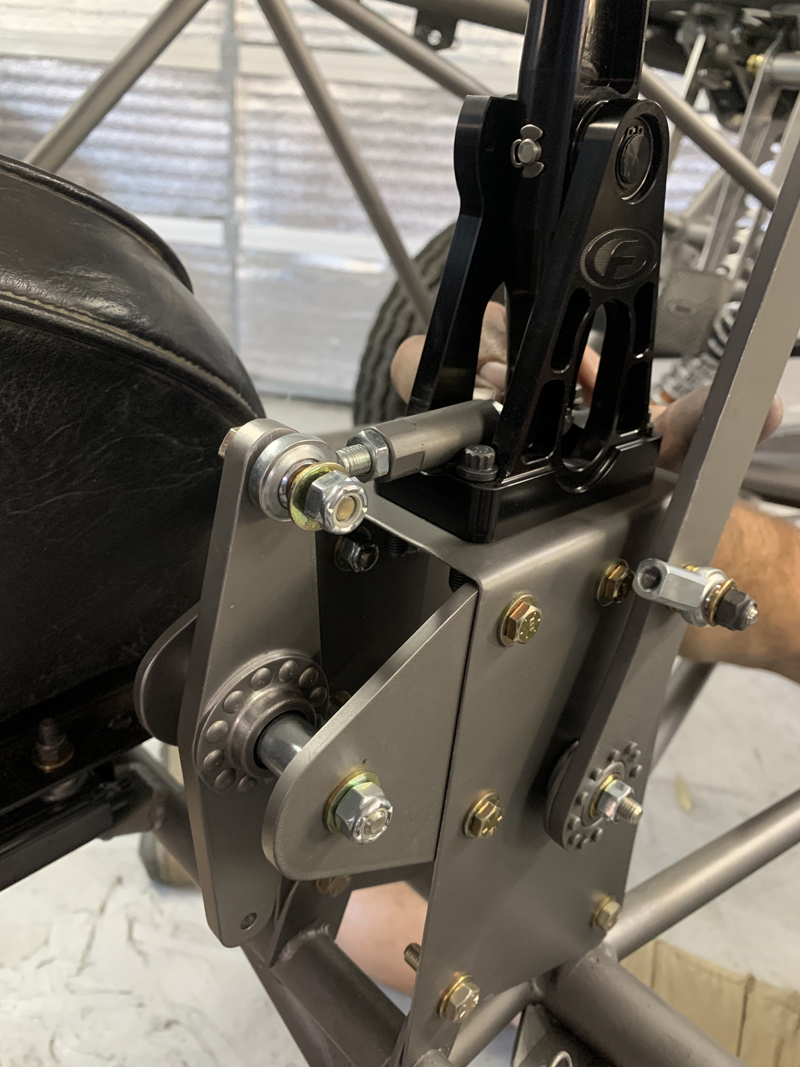

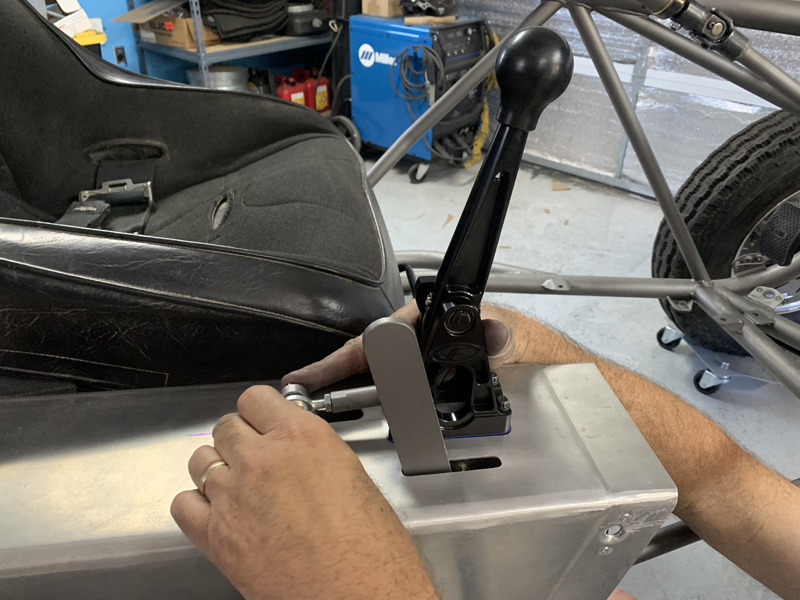

Now that the driver's seat is mounted, we

can move on to the design and fabrication of shifter and turning

brake mounts. We intend to mount the shifter on top of the

sheet metal "tunnel" and that will require that we fabricate a

support structure that will be mounted to the chassis inside the

tunnel. That support structure will provide a secure

mounting location for the shifter and the reverse lever (we're

not relying on the tunnel itself for support). We chose to

use a Fortin sequential shifter - we liked the look and feel

much better than the usual "Hargett" 2-lever shifter. Our

choice complicates the installation a bit; we'll need to

fabricate and mount a reverse lever in addition to reversing the

direction of shifter operation (the Weddle S5 transaxle we plan

to use requires a "push" from the shifter to "up-shift" and the

Fortin shifter "pulls" in the up-shift direction.....).

We'll solve both problems with the shifter support assembly -

we'll add a lever for reverse and a "bell-crank" to reverse the

shift direction.

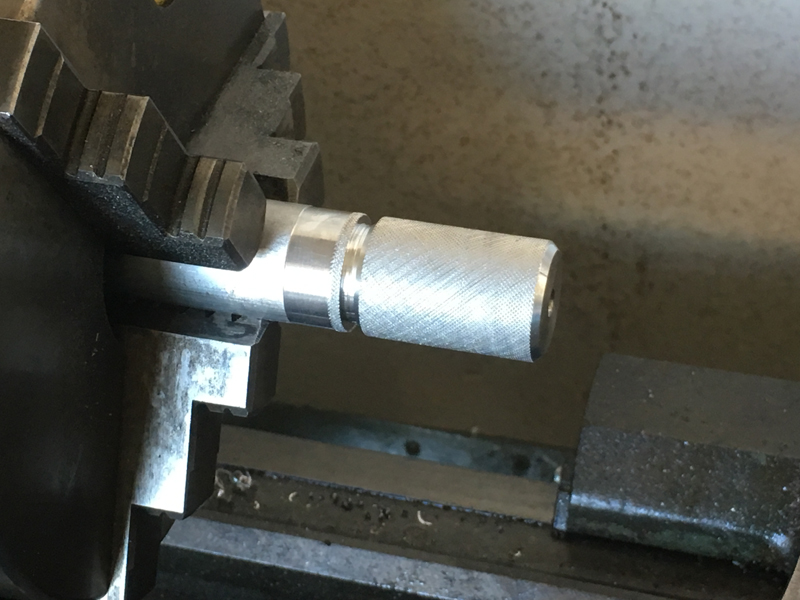

Milling the shift direction changing "bell

crank" to shape

Bell crank bearing ready to be riveted in

place

We opted to use a commercially available bell crank bearing

(aircraft part) for longevity, freedom of movement and minimum

slop - we fabricated the remainder. We'll rivet the

bearing to the bell crank arm - all the holes will be filled

with rivets. The bell crank converts a shifter "pull" to a

"push" in order to have correct shifter operation (shift lever

knob rearward for up-shifts and forward for down-shifts).

Reverse Lever Fabrication

We fabricated the reverse lever from 2024 aluminum and again

used a bell-crank bearing for smooth operation. We're

fortunate to have the proper riveting tools to make a secure

connection!

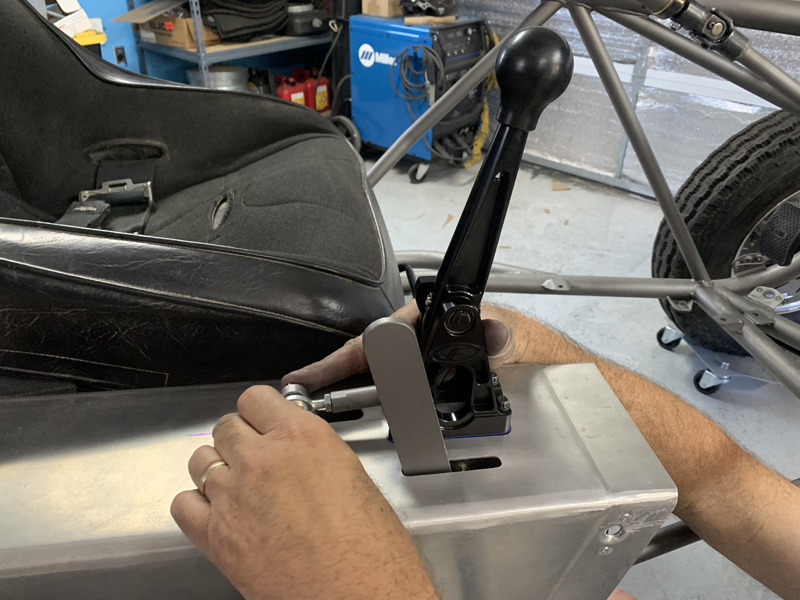

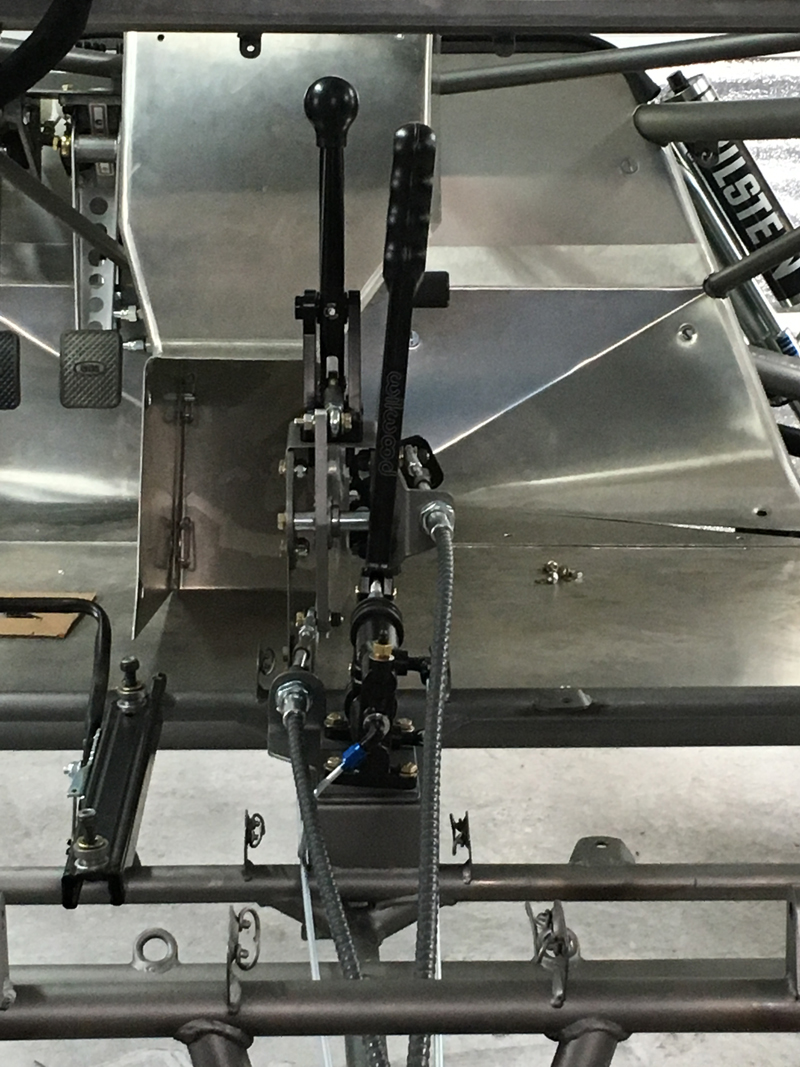

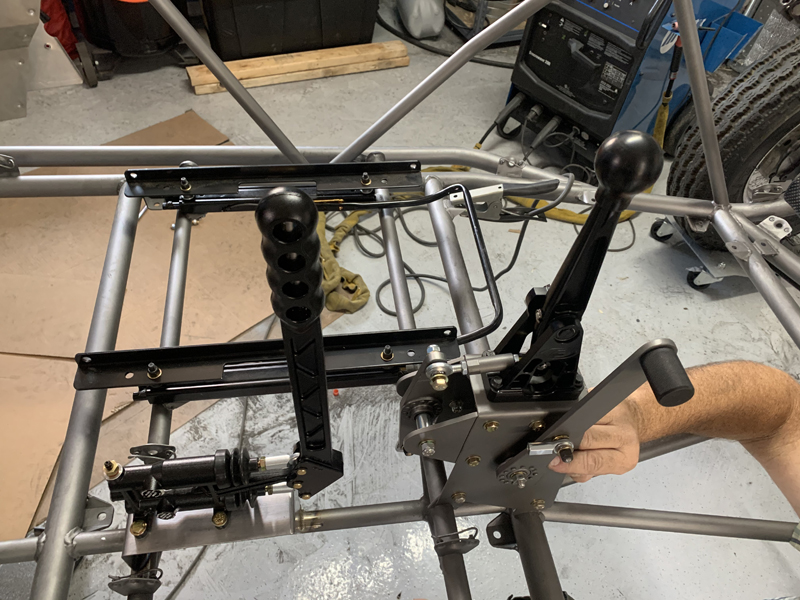

Shifter support structure with shifter,

reverse lever and bell-crank

Here, we're fitting the shifter support assembly to the chassis.

We need the assembly to nestle tightly up against the sheet

metal tunnel when everything is mounted; rather than weld the

support structure to the chassis, we chose to weld tabs and bolt

the support in place. That made it easy to get a perfect

fit.

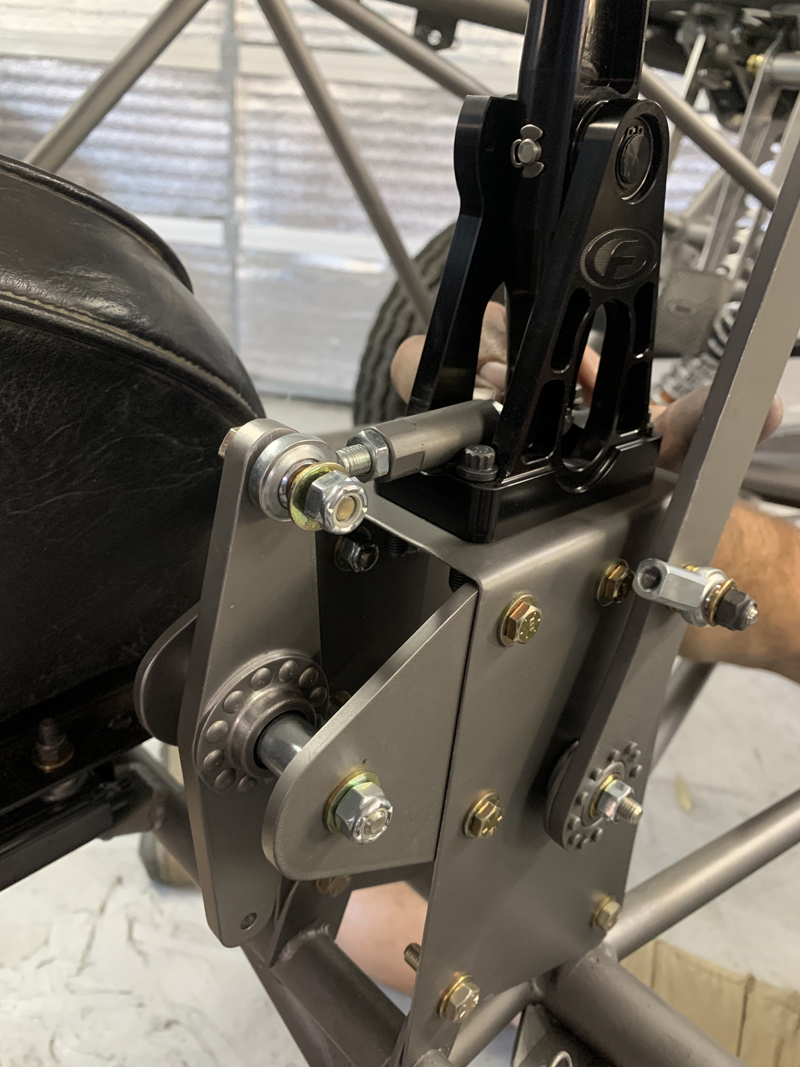

Shifter support assembly installed

Here you can see how the bell crank converts an up-shift

"pull" on the shift knob to a "push" at the shift cable

attachment point. The reverse lever is configured to

require a pull on the handle to select reverse. We'll need

to build a support structure for the "push-pull" cables; they

may be part of the turning brake mount - we need to be careful

to leave room for them once the turning brake assembly is

mounted and it'll probably end up near where the cables will

need to be mounted. This support assembly will be housed

inside the sheet metal "tunnel" and will not be visible except

for the shifter itself, the reverse lever and a small amount of

the upper bell crank and the push rod.

Sheet metal tunnel installed

We've done an initial trim of the tunnel for the reverse lever

and the bell-crank; we'll refine the fit once we determine

exactly how much "throw" we need to get (we think the shifter

throw is sufficient now). Once everything is finalized,

we'll make a cover for the bell-crank and push rod - just to

keep things from jamming it up. We'll be adding a small

"knob" to the reverse lever; it'll give us a more convenient

grip that should eliminate the possibility of scraped

knuckles.....

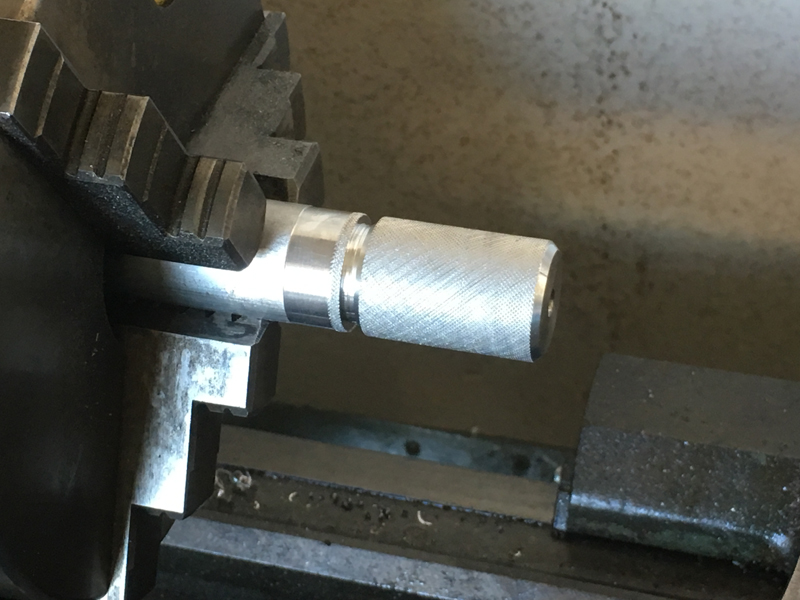

Fabricating the reverse lever knob

Knob painted and installed on reverse lever

Hopefully, the knob will save us a few

"busted knuckles" down the road.....

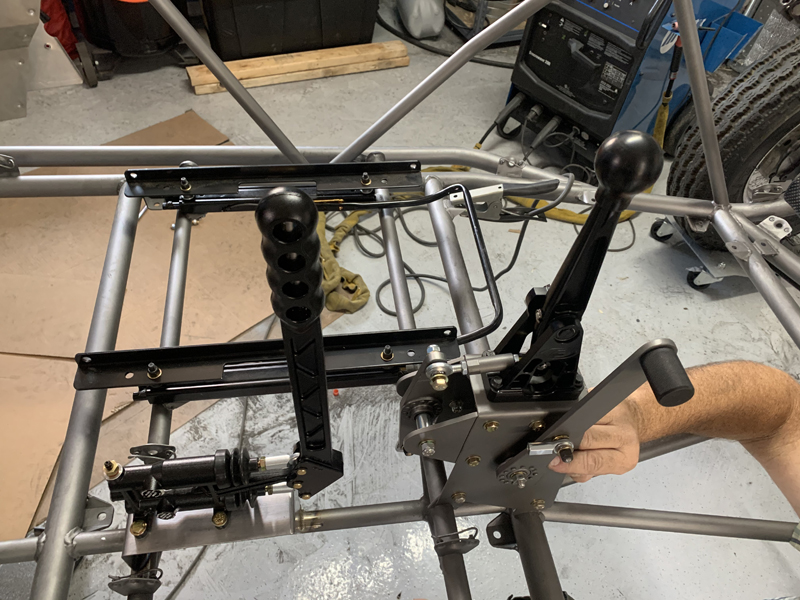

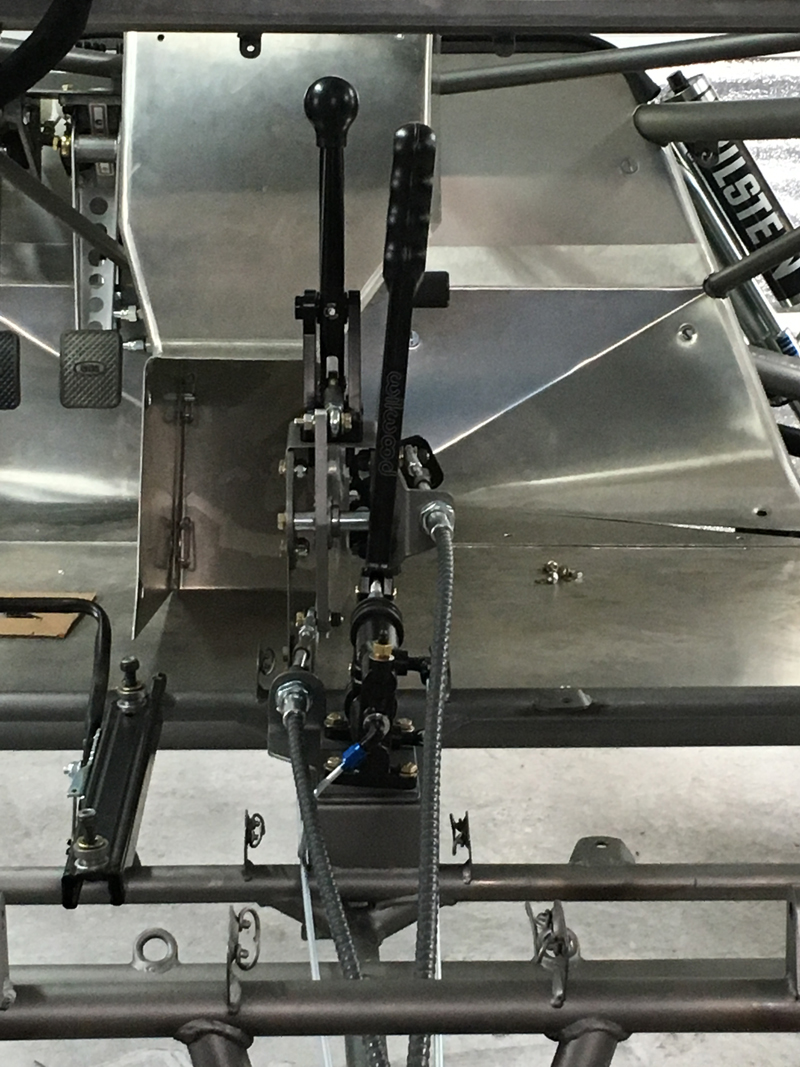

Turning brake mounted

We spent a fair amount of time finding the best location for

our turning brake assembly; we wanted it to be easy to

access/operate but didn't want there to be any interference with

the shifter or reverse lever. We settled on this location

after trying several different spots. We've angled the

turning brake lever away from the driver and towards the

co-driver just a little - it gives us a little more space

between the shifter and the turning brake handle and everything

is readily accessible.

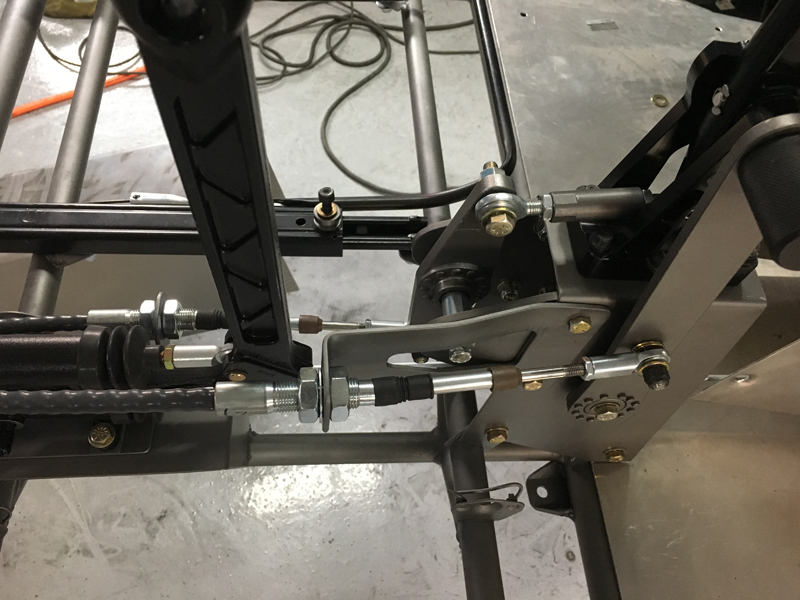

Shifter cable brackets and cables installed

The shifter cables straddle the turning brake assembly; our

decision to angle the turning brake towards the passenger side

required us to offset the reverse selector cable mount a small

amount for clearance, resulting in a small amount of

misalignment of the cable end. Note: the forward portion

of the tunnel is visible in this photo - it is not attached or

in its correct location.....

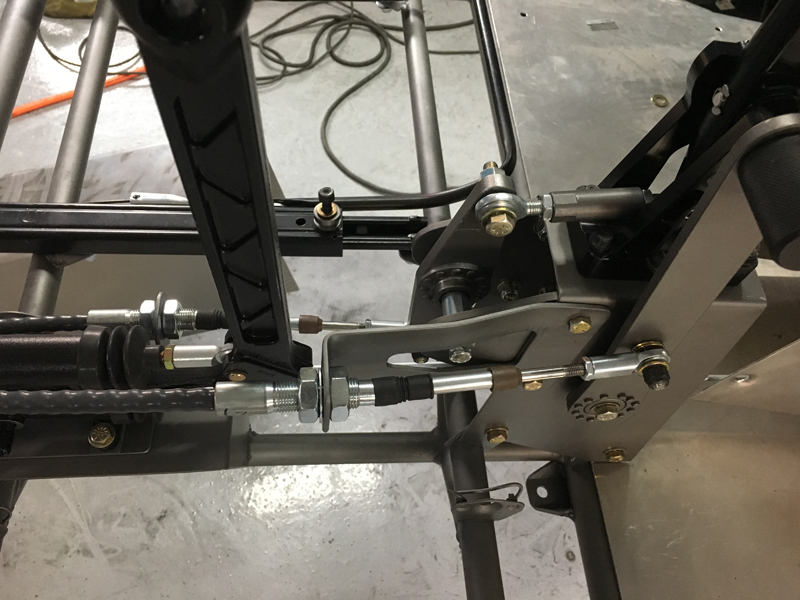

Reverse

lever cable mount and cable

Here, you can see the misalignment of the reverse selector

cable end - it operates smoothly but we may add a spacer under

the rod end to ensure that it continues to do so. Another

option is to open up the mount hole so that we can reposition

the cable inboard enough to eliminate the misalignment.

Forward gears selector cable and mount

installed

This mount is simply "sandwiched" between the turning brake

and its' mount. Easy installation with no modifications

needed. The cables are not yet attached at the transaxle

end or in-between. We'll keep the cables as straight as

possible while still mating to the transaxle at appropriate

angles to minimize any "free-play" in the shifter linkage.

We don't have our transaxle yet; that's a "big ticket" item that

we need to budget for so the aft ends of our cables will remain

unattached until then....

Center tunnel partially installed

Here you can see how everything fits inside the center

tunnel - we're thinking about our options for closing up the

turning brake handle slot in a way that allows free movement but

keeps foreign objects out - a rubber seal or a "brush" type

device are two of the options.

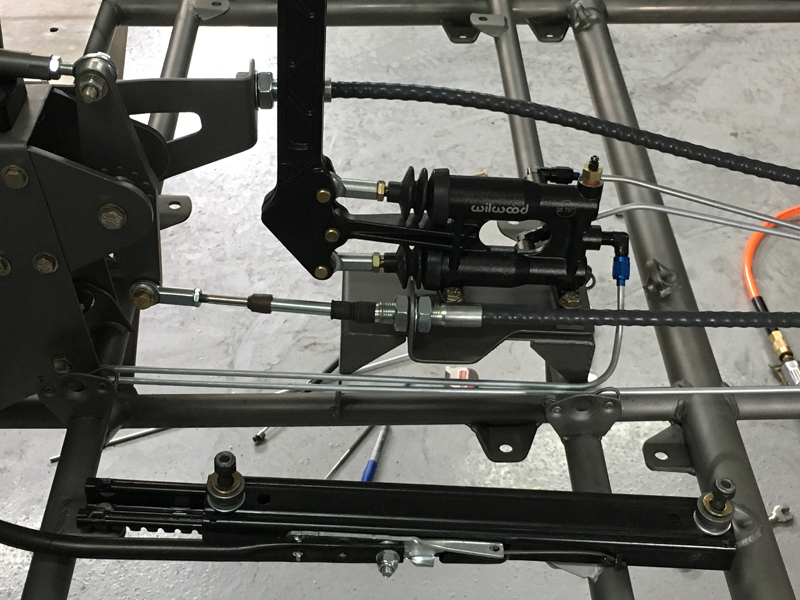

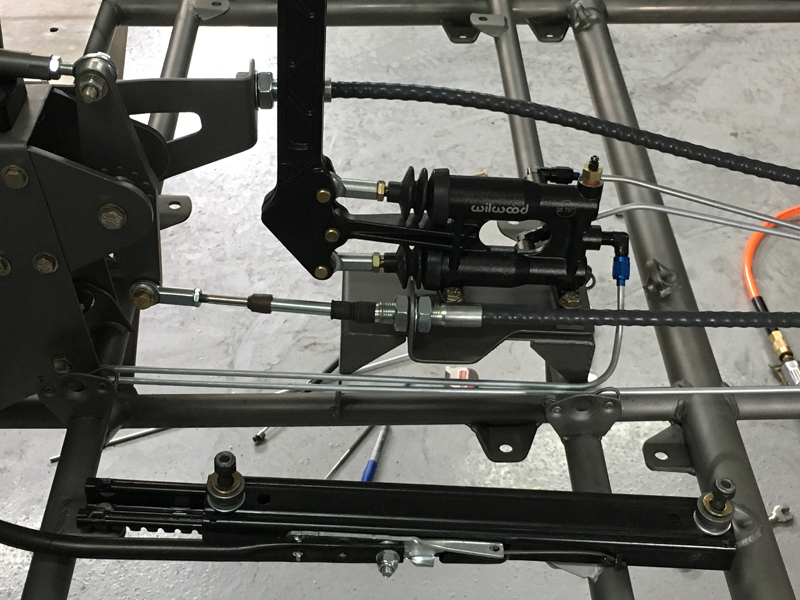

Brake and Clutch master cylinders and lines

Here you can see all three master cylinders and the

beginnings of their respective lines. The topmost cylinder

is for the clutch - no residual valve or light switch needed.

The middle cylinder is for the front brakes - only a brake light

switch needed before going to a firewall "T" then flex lines to

each front brake. The bottom cylinder is for the rear

brakes - a brake light switch and a residual valve before the

line connects to the turning brake assembly. All these

lines will be properly secured once complete. The power

steering lines will not be routed as seen here- they're just

hanging this way to keep them out of the way while we fabricate

the brake and clutch lines.

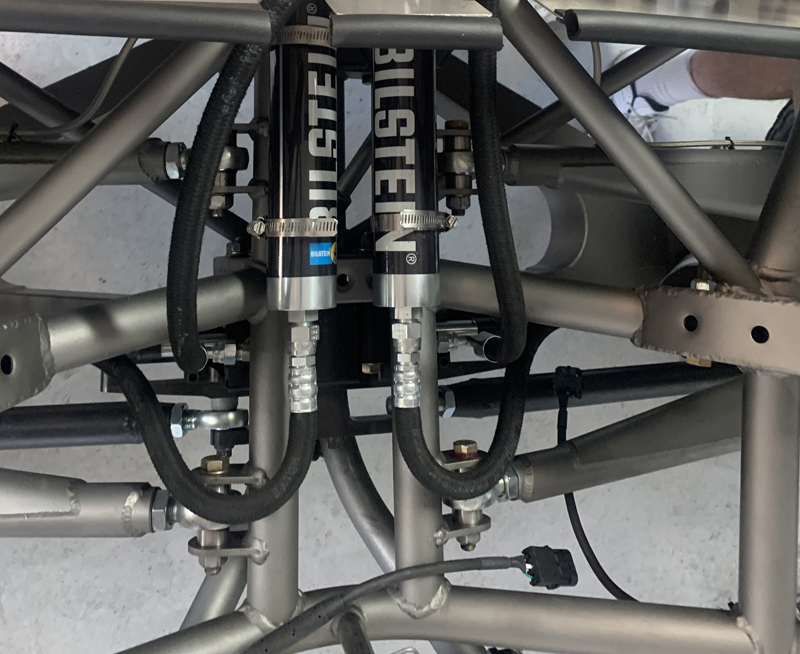

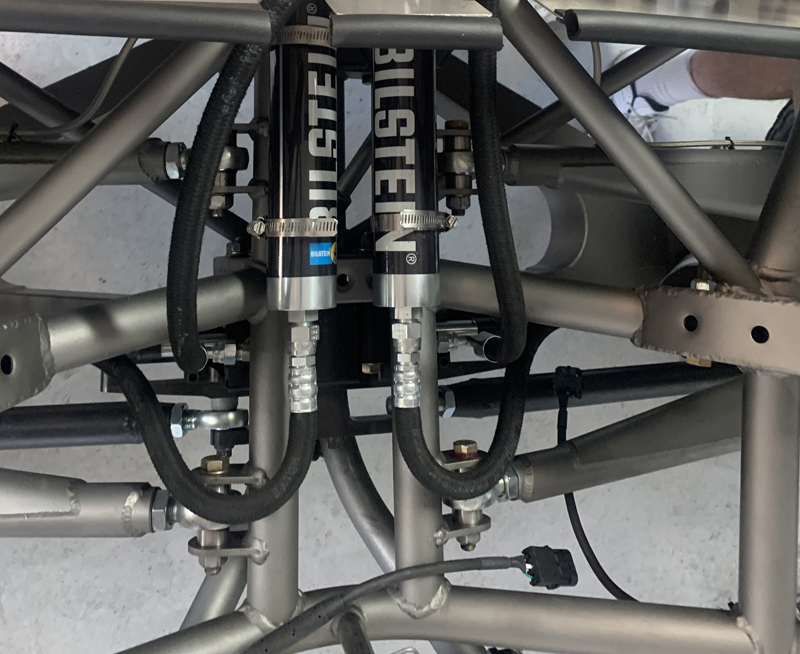

Turning brake lines

The turning brake unit is installed between the brake master

cylinder and the individual rear brakes - a single line in from

the pedal master cylinder and two lines out, one to each rear

brake. We've set up the lines so that we get both brakes

at the same time with pedal pressure, right brake with a pull on

the turning brake handle and left brake with a push.

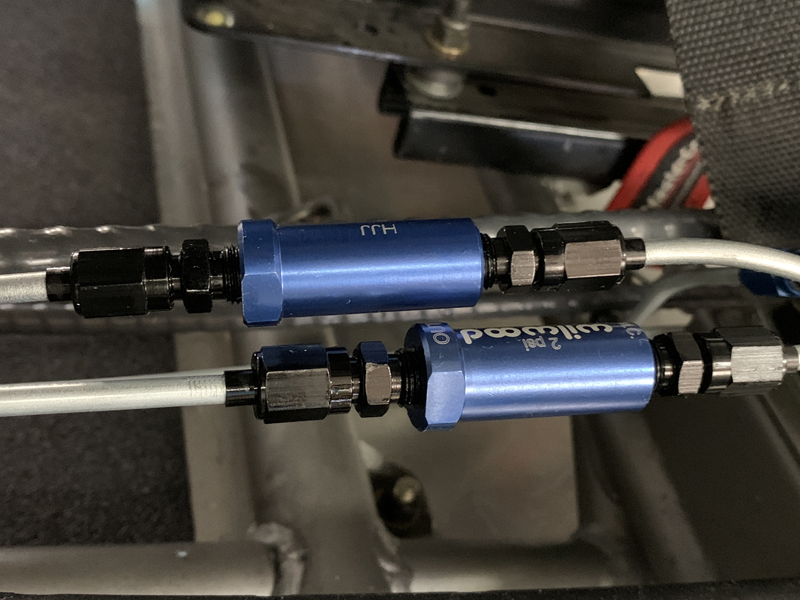

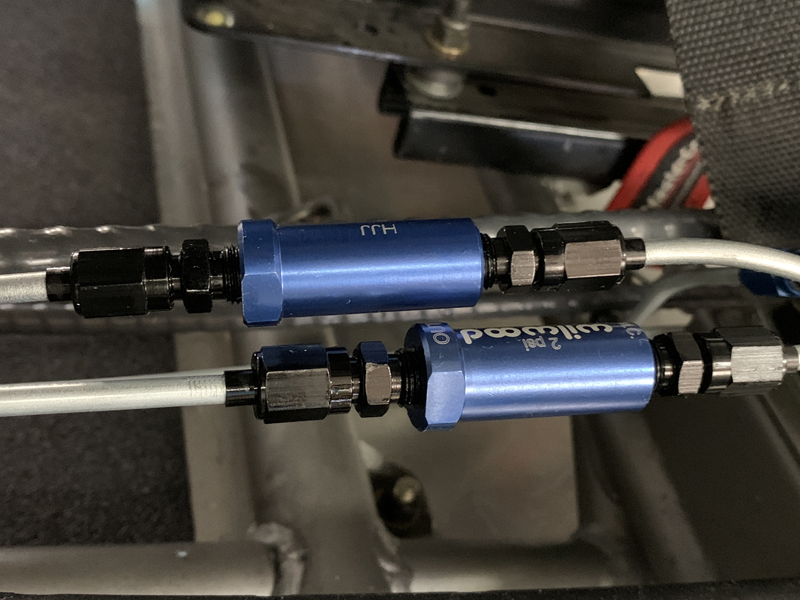

Residual valves installed after the turning

brake unit

We added these residual valves to the lines after the

turning brakes to help "firm them up". We may need to

remove the previously installed single valve near the brake

pedal master cylinder if there's too much "residual pressure"

now...

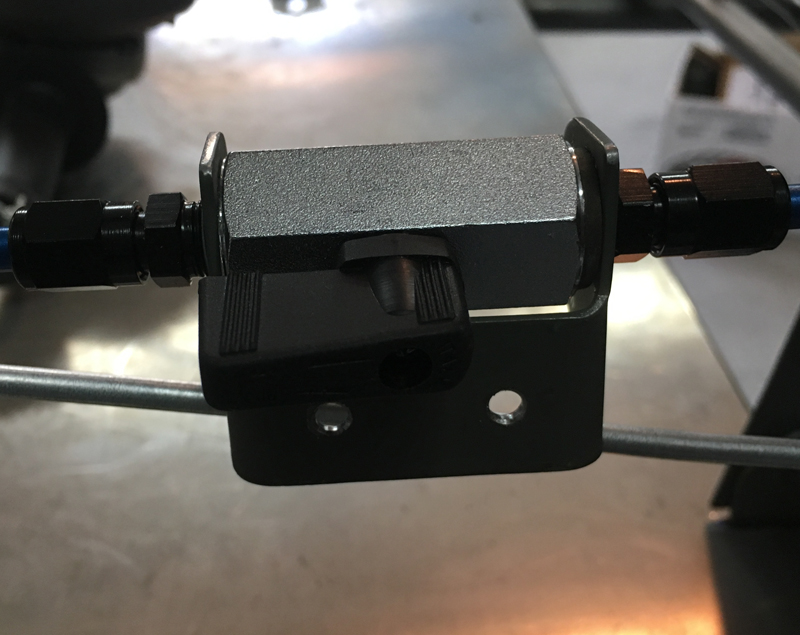

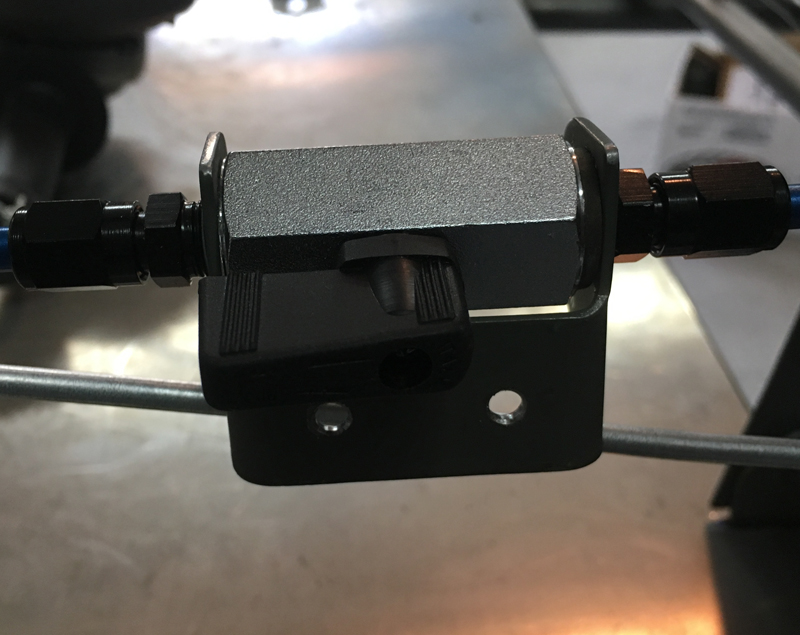

Parking brake "line lock" valve

We wanted to include some sort of parking brake capability,

knowing that we wouldn't use it often but that it would be

useful at some point..... This is a simple stainless steel

ball valve that will allow us to trap brake pressure to the rear

wheels, thereby acting as a parking brake. The valve

mounts to the inside of the tunnel sheet metal within reach of

the driver - the handle is outside the sheet metal while the

body of the valve will be inside.

Steering control valve to rack lines

fabricated and installed

The steering control valve and power rack hydraulic lines

fabricated and installed temporarily. Rather than creating

a new penetration of the foot well area sheet metal, we chose to

route the hoses along structure that already passes through the

area. There is plenty of clearance for them there and this

routing permits us to easily install/remove them without

disturbing the foot well area - it also allows us to remove the

sheet metal without removing the hoses....

|