|

"Mocking up" the radiator installation

We're fortunate to have photos of other Lothringer

pre-runner cars; they all have the radiator mounted in

this location and at this angle. Not wanting to "re-invent

the wheel", we're planning the same.

We'll fabricate a tubular support structure that allows us to

easily remove the radiator and fuel cell for service when

needed. The radiator is mounted at an angle in order

to facilitate the ducting of airflow to it.

Radiator support structure tacked in place

We bent the support hoop using our JD2 bender, fit it

to the radiator and chassis then tacked it in place.

Mount bosses welded to radiator

We fabricated the aluminum "mount bosses" on our

lathe then Trevor welded them in place.

1/4" NPT Boss added to radiator for surge

tank connection

The cooling system has three main components: the radiator,

the surge tank and an overflow tank. The surge tank serves

to eliminate air trapped in the cooling system; this boss allows

any air in the radiator to vent to the surge tank which then

backfills the radiator with coolant. The surge tank vents

to the overflow tank when necessary.

Radiator in place

With the support hoop tacked to the chassis, we

installed the radiator to verify the fit. Four of the six

mount bosses are engaged at this point; we'll fabricate and

install the lower two mount tabs next. Those mount tabs

will require that we add a small chassis tube on each side.

Trevor "final" welding the radiator support

hoop in place

We'll be adding small gussets

to the support hoop/chassis joints, otherwise they'd be "fatigue

crack" problem areas.

Radiator support hoop gusset installed

This might not be necessary but it's cheap insurance...

Removable lower radiator support tab

The lower radiator supports must be removable because they

would be in the way when we want to remove the fuel cell.

Once we remove the main tabs, we are left with small mounts that

don't obstruct the fuel cell's removal.

Due to the location of the radiator and the

fact that this car has a windshield, we need to supplement the

natural air flow with a duct to direct air to the radiator from

above the roof line and below the roof rack; there's a

rectangular duct there that provides "ram" air from above the

windshield.

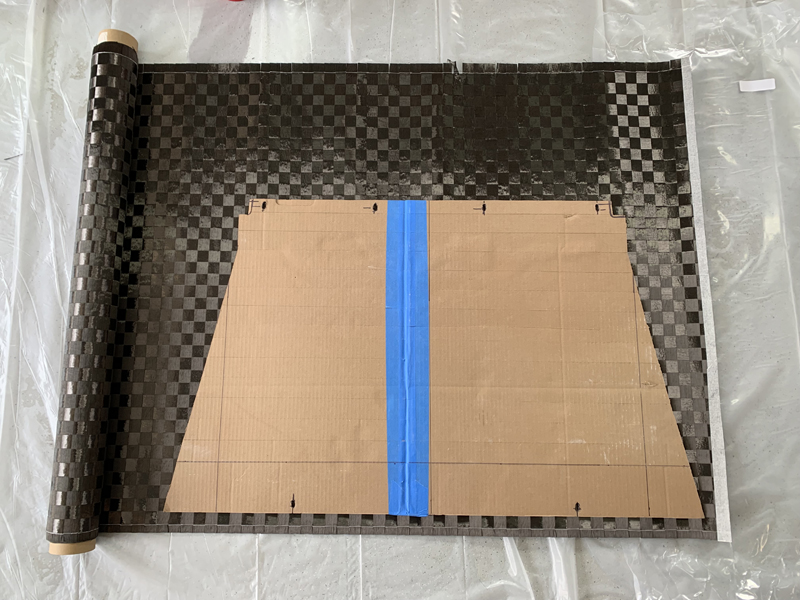

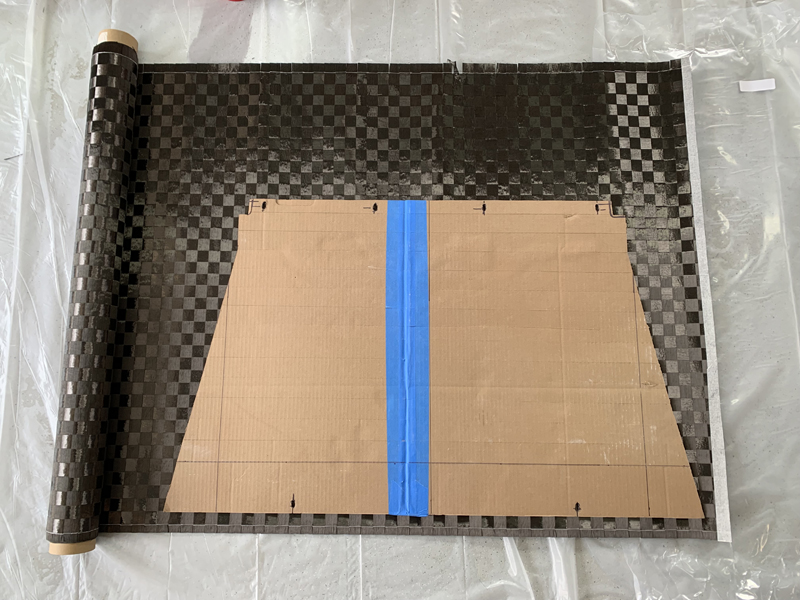

Making patterns for the cooling air duct

mold

The windshield will disrupt the flow of air to the radiator

at high speed - the duct will route air from the passage between

the roof and roof rack to ensure adequate airflow at all speeds.

Here, you see Trevor's patterns for the female mold we'll

construct in order to produce a one-piece carbon fiber duct.

The duct will have rounded corners between the sides and the

upper piece - the "square corners" you see here are only for

creating the basic mold structure... We'll

essentially duplicate the aluminum ducts Kent Lothringer

fabricates for his "turn-key" pre-runners using carbon fiber for

ours.

Plexiglass duct mold

Trevor made the duct mold on the car using sheets of

Plexiglas with bondo in the corners for a smooth radius between

the sides and top. Once fitted and glued together, he

removed it from the chassis and added the rounded corners.

The mold was waxed and sprayed with a silicone mold release

agent before the actual layup.

Cutting the carbon fiber cloth

Once the mold was ready, we cut out all the layers of carbon

fabric. Here, we're cutting the first layer (25mm tow) - the one that

will be visible from outside the car. Several reinforcing layers

(2X2 twill) were cut in preparation for the actual molding process so that

the final part will be strong and stiff once the resin cures.

Trevor laying the 25mm "tow" top layer

We have the mold "upside down" to make the layup easier for

us; in this position, the bottom is actually the upper portion of

the finished duct. You may be able to see that the corners

have a generous radius; carbon fiber doesn't do sharp bends

well. In addition to helping ensure that the cloth

conforms to the mold easily, we think that rounded corners have

a more "finished" look... The first layer will be visible from the outside so we chose

a 25mm tow "checker board" pattern. Several 2X2 "twill"

reinforcing layers back the surface layer for strength and

rigidity.

Layup complete

The resin begins to "cure" as soon as it's

catalyzed. The "pot life" (working time) is determined by

the choice of catalyst, size of the batch and temperature - It's hard to pin down precisely

how long you have to work with each batch.

Having all the fabric cut to shape and working quickly is

helpful in ensuring that you can complete the layup with a

minimum of wasted resin. Even with everything ready, it's

difficult (nearly impossible) to work quickly enough to complete

all the layers with a single batch of resin. As the

catalyzed resin starts to "thicken", it will no longer "wet" the

cloth, leading to voids and de-laminations if you continue to

use it. As soon as any thickening is evident, set it

aside, mix a new batch and continue the layup with the newly

mixed resin. Mixing small resin batches as needed is

usually the less wasteful method for large parts...

Once the layup is complete, there is a time

during the cure where it's firm enough, but not too

hard to trim easily with a razor blade. That time is

determined by periodically checking the state of cure by hand -

when it's stiff but not hard, it's time. Trimming with a

razor blade at that point is more precise, easier and cleaner than

waiting for a full cure and using a cut-off wheel (we'll still

have to do some of that)... Now

that we've done the trim, it's just a matter of waiting for a

full cure and removing the part from the mold.

Radiator duct out of the mold

The radiator duct came out of the mold easily

with the exception of the rounded corners - they came out with

the filler we used to create the radius still attached...

Not a huge problem; Trevor chipped it all away without damage to

the actual part. This type of wet layup (no vacuum bags or

resin infusion) produces a fairly smooth surface but leaves

pinholes and small surface voids that must be handled

individually during the "finishing phase". The finishing

phase consists of filling the voids/pinholes, sanding, filling

again, sanding, possibly more filling/sanding and then a final

gloss coat of resin over the smooth part. That's a fair

amount of work; an aluminum duct would probably have been

quicker/easier but we'll have a custom, one-off,

carbon fiber duct that we created...

Radiator Duct sanded smooth and flat

Trevor spent hours sanding the duct smooth and flat in

preparation for a final gloss coat. You can still see a

couple of very small "low spots" in this photo but once the

gloss coat is applied, they'll mostly disappear. Prior to

applying the gloss coat, we'll drill the mounting holes and

refine the fit of the duct to the radiator and chassis.

Test-fitting the radiator duct

Prior to final finishing, we wanted to check and "fine tune"

the fit at the radiator and chassis. This is the first

time the final part has been on the car; it looks like a pretty

good fit with only minor adjustments needed. We will not

allow the duct to actually contact the radiator anywhere except

the top face where they bolt to each other - the carbon fiber

would eventually wear a hole in the radiator anywhere they

rubbed against each other...

Duct side support tab

We installed a tab on each side of the radiator to support

the duct "wings". These will keep the sides of the duct

from "flapping in the breeze" but more importantly, they'll keep

the duct from rubbing on the radiator and possibly wearing a

hole in it...

First coat of finishing resin applied

This is only the beginning of the finishing process; we'll

need to wet sand smooth and apply at least one more coat of

resin before we get the smooth, glossy look we want. The

25mm "tow" pattern really pops now.

Radiator and duct installed

We think the duct looks spectacular on the car, especially

out in the sun! It fits beautifully and will serve it's

purpose with style...

Trevor created a work of art that'll be functional as well.

|